What is Sand Control?

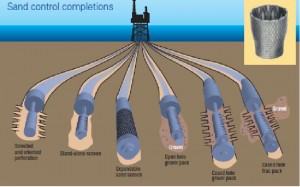

By Oilfield glossary, sand control is one of the process of well completions. “The installation of equipment or application of techniques to prevent migration of reservoir sand into the wellbore or near-wellbore area. In weak formations, sand control may be necessary to maintain the structure of the reservoir around the wellbore. In other formation types, the migration of sand and fines into the near wellbore area may severely restrict production. Each of these conditions requires different treatments. The principal sand-control techniques include gravel packing and sand consolidation.”

Sand control focusing on gravel packing, the most popular choice.

What is Gravel packing?

Gravel packing involves the complete placement of selected gravel across the production interval to prevent the production of formation fines or sand. Any gap or interruption in the pack coverage will enable undesirable sand or fines to enter the producing system.

It includes the following components:

1 production tubing

2 production casing

3 Gravel-pack packer

4 Gravel placed in casing and perforations

5 Gravel pack screen

6 Sump packer

Sand control V.S. Solids control

Sand control has always played an important role in oil production, but solids control plays an important role in oil well drilling. They are utilized in different area.

Solids control is a technique used for well drilling to provide prepared drilling fluids for drilling rigs. Drilling fluid maintenance cost, clean up, and disposal cost as well as the overall cost of boring can be reduced dramatically when proper solids control techniques are utilized.