GN Solids Control Co., Ltd. is a Chinese company specializing in the design, manufacturing, and service of solid control systems and related equipment for the oil and gas drilling industry.

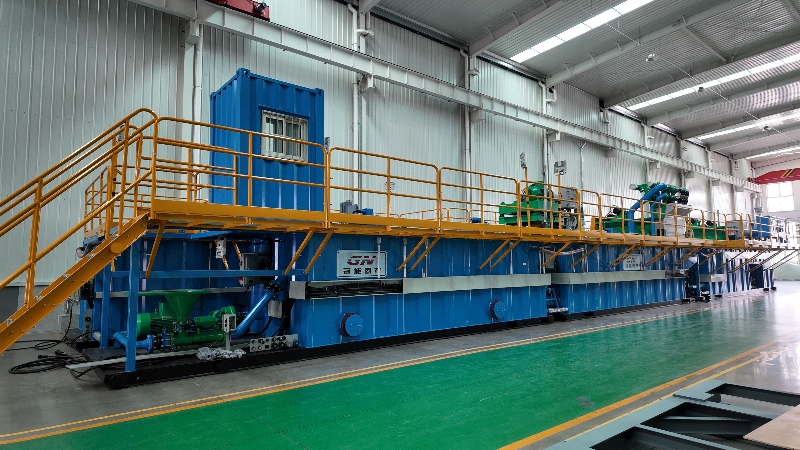

GN Solids Control provides specialized mud recycling systems for trenchless drilling (HDD, microtunneling, pipe jacking) to maximize fluid reuse, reduce costs, and minimize environmental impact.

Why Use a Mud Recycling System in Trenchless Drilling?

Recovers expensive drilling fluids (bentonite, polymers).

Reduces disposal costs of waste slurry.

Maintains optimal mud properties for lubrication and bore stability.

Prevents jobsite pollution (compliance with EPA, local regulations).

Key Components of GN’s Trenchless Mud Recycling System

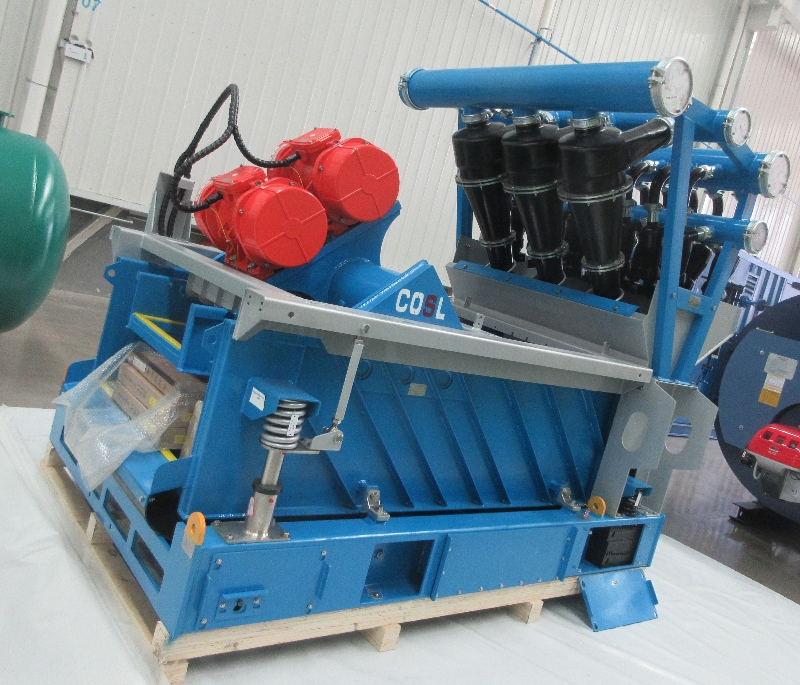

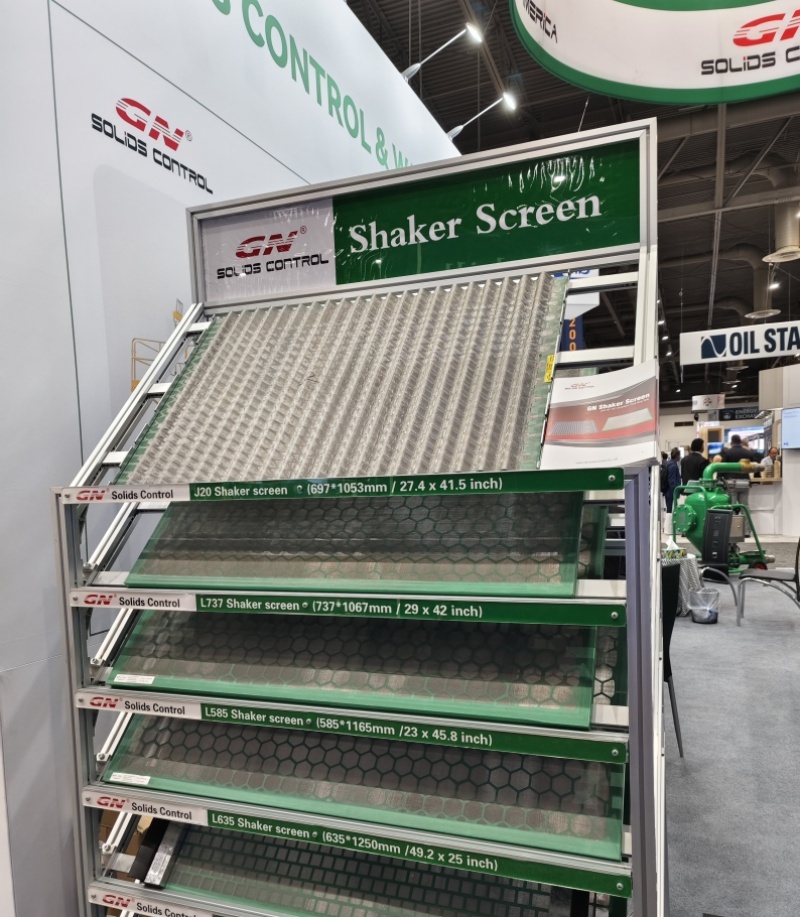

- Shale Shaker (Primary Solids Removal) GNZS Linear Motion Shaker

Removes coarse cuttings (≥75μm).

Adjustable screen mesh for different soil types.

- Desander & Desilter (Secondary Cleaning) Hydrocyclones (10-50μm separation) for finer solids.

GNZJ Series – Compact design for HDD rigs.

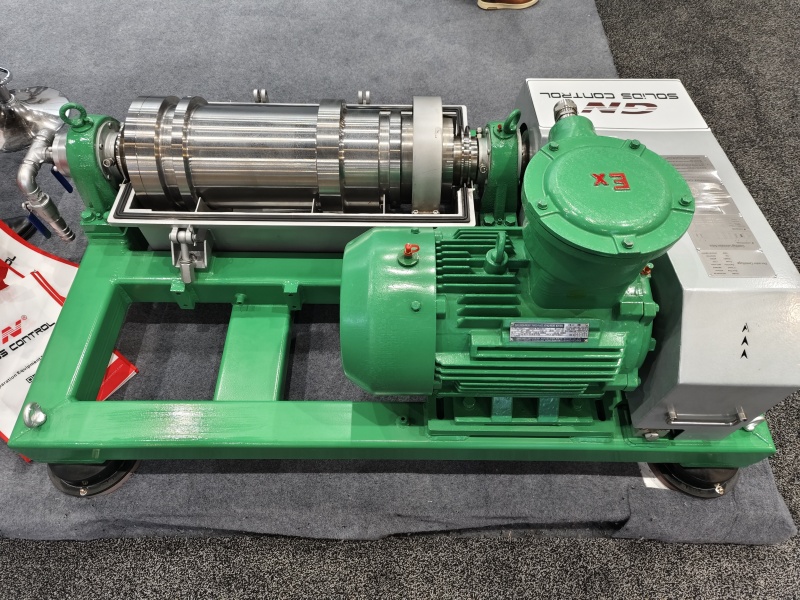

- Decanter Centrifuge (Ultra-Fine Separation) GNLW Series – Recovers bentonite & removes colloidal solids (down to 2-5μm).

Variable Speed Control – Adjusts for different slurry densities.

- Mud Mixing & Storage System Jet mixing hopper for fresh mud preparation.

Agitation tanks to maintain slurry consistency.

- Cuttings Handling (Optional) Screw conveyor – Transports separated solids to disposal.

Vertical cuttings dryer (VCD) – Further reduces fluid on waste (for <5% moisture).

System Workflow

Used slurry returns from the borehole.

Shale shaker removes large cuttings.

Desander/desilter takes out medium-fine particles.

Centrifuge polishes mud for reuse.

Clean mud is pumped back into the system.

Solids are discharged for disposal.

Applications

Horizontal Directional Drilling (HDD)

Microtunneling & Pipe Jacking

Utility Installation (Fiber, Gas, Water Lines)

Geothermal Loop Drilling

Why Choose GN Solids Control?

✅ 15+ Years in Trenchless Mud Recycling

✅ Global Support (USA, Europe, Middle East, Asia)

✅ API & CE-Certified Equipment

Any cases request, find Michaelsong contact.

Whatsapp: + 86 178 0179 9913(prompt reply)