Dredge dewatering system are Integrated from Dredged slurry Separation equioments. As a drilling mud system manufacturer,we are now moving to a new division of slurry separation for Dredge dewatering system.

Contact now:Dredged dewatering Equipments Sales

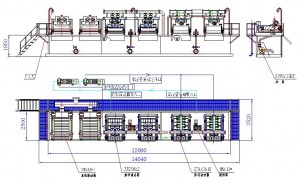

The dredge dewatering Equipments

Dredged slurry tanks (Ladder、slide walk、handrail、valve, mud pipe line, clean gate)

Sand Pumps,Centrifugal pump

Electrical Requirements:460v, 60 Hz, 3Ph, 350 Amps or 380v, 50 Hz, 3Ph

Solid Separation Equipment

Two ZS Scalping Shakers model ZS830×108-3

2 Desanders with ZS830×108-3 Shakers

2 Desilter with ZS830×108-3 Shakers

Thru put Dredged slurry Dewatering Capacity

2000 gallons per minute, continuous.

Slurry Agitators

Two 7.5kw with double impeller

Solids Loading in Feed

15% by weight for best performance

Mud Guns

Features of Dredge Dewatering System Continue reading