What is the difference in operation between positive displacement pump and centrifugal pump?

Positive Displacement Pumpswill not p roduce the same flow at a given speed (RPM) no matter the discharge pressure.

Positive Displacement Pump must not be operated against a closed valve on the discharge side of the pump because it has no shut-off head like Centrifugal Pumps. A Positive Displacement Pump operating against a closed discharge valve, will continue to produce flow until the pressure in the discharge line are increased until the line bursts or the pump is severely damaged – or both.

The positive displacement pump can be applied as

- rotary lobe pump

- progressing cavity pump

- rotary gear pump

- piston pump

- diaphragm pump

- screw pump

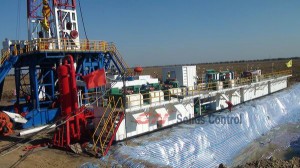

When positive displacement pumps serve as a screw pump for feeding drilling fluids decanter centrifuge, when you change the frequency of the main motor through the VFD control panel, the treating capacity of decanter centrifuge will change, so the flow rate need to be lessed.