GN decanter centrifuge can be used for drilling mud treatment, waste water treatment, to remove fine solids from liquid medium, thus to adjust the physical property of the liquid medium, eg. Viscosity, density, weight etc. GN can offer high speed & middle speed centrifuges, treating volume is also different from small capacity to big capacity. GNLW 223 is GN mini centrifuge, small capacity, high speed, which can be used for waste water treat for diamond drilling. The speed can reach to 3800RPM and treating volume is about 6m3/h. Price of GNLW223 is also fit for diamond drilling fields. GNLW553 is GN big bowl big volume decanter centrifuge. The volume can be 500gpm and the speed is adjusted from 1800RPM to 2500RPM. The big bowl centrifuge is specialized for fast drilling, or other type of application. GNLW363 is GN most popular model centrifuge. We have over 150sets centrifuge for annual sales amount. The centrifuge is widely used in solids control, waste management, waste water, environmental projects and so on. For this model, we can offer 4 types centrifuge: GNLW363CD fixed speed centrifuge, economic configuration GNLW363CD-VFD variable speed centrifuge, economic configuration GNLW363CG fixed speed centrifuge, premium configuration GNLW363CG-VFD variable speed centrifuge, premium configuration  Continue reading

Continue reading

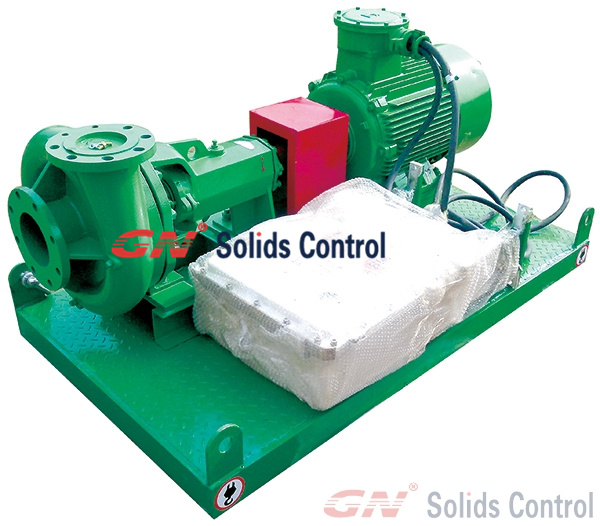

GN various electric motor pumps for different application

GN Solids Control is mainly focus on solids control equipment manufacture and drilling waste management manufacture. Pump, as system transfer part, make the total system to be active.

GN Solids Control equipment including: shale shaker, mud cleaner, desander, desilter, centrifuge, screw pump, centrifugal pump, submersible slurry pump, mud hopper, mud agitator, mud gun, mud tanks et.

GN drilling waste management equipment including: vertical cuttings dryer, screw conveyor, waste management centrifuge, High G dryer shaker, solidification unit, fixation unit, flocculent unit, dewatering unit, thermal desorption unit etc.

GN various pumps including: GN Screw pump, GN centrifugal pump, GN shear pump, GN submersible slurry pumps etc.

1) GN Screw pump: This pump is ideal pump for feeding decanter centrifuge. It is displacement pump without agitating the drilling mud when feeding. We can offer China brand screw pump with lower price, as well as Germany brand screw pump with much better working performance and longer lifetime. Price of Germany brand screw pump is higher than the first one.

2) GN centrifugal pump: This pump is used for feeding the desander cones & desilter cones in drilling mud system. It can also be used with mud hopper, to circulate the drilling chemicals and mixing the chemicals.

Drilling Cuttings Solidification Unit shipping to Africa

GN Solids Control is China & USA based leading supplier for solids control equipment & drilling waste management equipment. Our equipment includes solids control equipment, mud system, drilling waste management equipment etc.

Recently, we ship one set drilling cuttings solidification unit to Africa client. The client is local professional oil Service Company with many years experience in solids control & drilling waste management. Formerly, the client wants to buy US brand fixation unit. However, the client checks the design of our fixation unit, and then compare the price with US brand fixation unit. Finally, the client choose GN Solids Control brand for the fixation unit.

GN drilling cuttings fixation unit composed of below items.

1) One hopper to collect drilling waste from shaker discharge / mud cleaner discharge / centrifuge discharge

2) One screw conveyor connected with waste hopper, transfer the screw conveyor to mixing blender.

3) Two sets stainless steel chemical box with screw conveyor installed on both side of blender, to add curing agent or cement

4) One mixing blender to mix the curing agent / cement with drilling waste.

Dual Centrifuge System for Mining Project

Mining project may generate some waste water / waste mud which need to be treated before discharge. GN Solids Control mud treatment system can also apply in this field. Recently we have a similar project for Philippines. It is dual centrifuge system for Mining project

The Dual centrifuge system configuration as below:

1) One set shale shaker to remove the coarse solids particles, separation points above 100microns to 200microns.

The shale shaker GNZS594E-HB is GN 4 panel shaker, which is replacement shaker as Swaco Mongoose. Similar design with composite material shaker screen can reach high treatment performance. For more info of GN Shale shaker, pls check from GN shale shaker website.

2) Two sets high speed centrifuges to remove the fine solids particles, separation points above 2-5 microns.

The centrifuge, GNLW363CG-VFD is GN high speed & variable speed & high configuration decanter centrifuge, which competing with US/European centrifuge brands. Centrifuge applications including

a. High performance water based mud treatment for oil drilling rig solids control

b. High performance oil based mud treatment for oil drilling rig solids control

c. High performance waste water treatment for oil drilling rig drilling waste management

d. High performance barite recovery / mud weight cutting for oil drilling rig solids control

Chemical enhancing centrifuge system for oily sludge

Compared with drilling cuttings (discharged from shale shaker), oil sludge is more difficult to be treated and recycled. To have better understanding of oily sludge, we have to know what oily sludge is & where it is from. Pls get more info from google search engine. And from below chapter, we can know how to treat the oily sludge and what results we can get after treatment.

GN Solids Control is China & USA based leading manufacturer for solids control & drilling waste management equipment. Studied together with China Oilfield Service Limited (short for COSL), GN Solids Control develop the first sets of Chemical enhancing centrifuge system for oily sludge treatment in beginning of 2015, after jobsite test and application, the result is very good. COSL repeat another 2 sets centrifuge system order in past several months.

1) Chemical enhancing centrifuge system configuration:

GN Total Solution for drilling waste management

GN Solids Control is the first China drilling waste management equipment company who can offer total solution equipment for drilling waste management Service Company.

Regarding Oil based mud drilling cuttings, the total solution of drilling waste management including below steps:

Step 1: Vertical cuttings dryer. Use this VG dryer to treat the drilling cuttings, recover the valuable oil based mud. The OOC after treatment can be 3%-5%.

Step 2: Thermal Desorption Unit. After VG dryer, the solids can go to TDU for non-hazardous final treatment. After TDU, the water, oil and solids can be separated in accepted degree which comply with most of country’s government policy on environmental protection

Step 3: Decanter Centrifuge. After VG dryer, the liquid part (drilling fluids) can go to centrifuge to remove the fine solids and go back to active mud tank for reuse. Some client let the liquid part discharged from VG dryer go back to active mud tank system directly. This is also OK.

Dual Centrifuge system for waste management

GN Solids Control just receive order from waste management service company (call this client WMSC for short in below chapter). WMSC is waste management service company with many years jobsite experience, their main client is CNPC and SINOPEC. With China new policy on environmental protection, WMSC is faced with booming business project with CNPC & SINOPEC, requiring more waste management equipment to support their project. As China leading manufacturer for solids control equipment & waste management equipment, GN Solids Control definitely become their main supplier.

WMSC already use our decanter centrifuge & vertical cuttings dryer & high G dryer for over 2 years for waste management project. They give high praise on GN equipment. Pls see more details of below.

GN Super high speed centrifuge for waste water treatment

GN Solids Control is professional original manufacturer for solids control equipment & drilling waste management equipment. Decanter centrifuge & vertical cuttings dryer is the key equipment of GN. In the past years, we offer over 100 sets centrifuge & over 30 sets vertical cuttings dryer every year to the oil & gas drilling field, HDD drilling, CBM drilling, diamond drilling etc. Recently, GN big bowl super high speed centrifuge GNLW363CG-VFD come to market, with G force 2908@3800RPM bowl speed, which is good choice for waste water treatment.

GN Solids Control can offer different type centrifuge, like

Small bowl mini centrifuge, middle bowl centrifuge, big bowl big volume centrifuge

Low speed centrifuge, middle speed centrifuge, high speed centrifuge, super high speed centrifuge.

GN Verti-G dryer for drilling cuttings treatment

GN Solids Control is leading manufacturer for Vertical cuttings dryer ( Verti-G dryer) & decanter centrifuges, which are key equipment for solids control & drilling cuttings treatment. Up to now from 2012, we already exported over 300 sets centrifuges & 50 sets vertical cuttings dryer to international oil drilling field and domestic drilling companies. The premium performance and reasonable price win good reputation for GN Solids Control.

Recently, our after sales team just come back from an Africa Drilling Company rigsite.( We call it ADC in this chapter). ADC is a drilling company with 7 land drilling rigs and all the rigs is under drilling process. From 2013, ADC contact our company and visit our factory (location is close to Beijing) many times. After that, ADC issue many big orders to us, totally including:

1) 5 sets Verti-G dryer for drilling cuttings treatment, attached with:

- 5 sets high skid to install the vertical cuttings dryer,

- 5 sets screw pump for flushing the Verti-G dryer,

- 15 sets screw conveyor to transfer drilling cuttings for feeding or for discharge.

- 5 sets one year recommended spare parts.

Verti-G dryer with screw conveyor to Middle East

GN Solids Control Verti-G dryer (vertical cuttings dryer) is verified high quality products in many drilling rig site, like Shell jobsite, Baker Hughes drilling site etc. Even compared with CSI vertical cuttings dryer, in some bad mud cuttings conditions, GN Solids brand Verti-G dryer can also work in high performance. This is also the technology accumulation with many years research, test and jobsite experience.

Last year, we have exported over 10 sets verti-G dryer with screw conveyors to Middle East, the main client is NIDC. As Iran government strict policy on environment protection, GN Solids Control have a big chance to match large quantity of verti-G dryer with screw conveyors for NIDC drilling rigs.

One package of verti-G dryer with screw conveyors including below items: