A few days ago, two sets of 20 cubic waste slurry treatment systems designed and manufactured by GN Solids Control for Singapore customers have been used in the customer’s shield slurry treatment site.

The waste slurry treatment system complies with Singapore’s national environmental protection requirements and adopts a containerized design. The system is mainly composed of a decanter centrifuge, a flocculation system and a container, which satisfies the integration, harmlessness and reduction in the urban construction process. It also adopts sealing and noise reduction treatment as a whole, which reduces the impact on the lives of surrounding residents during the construction process.

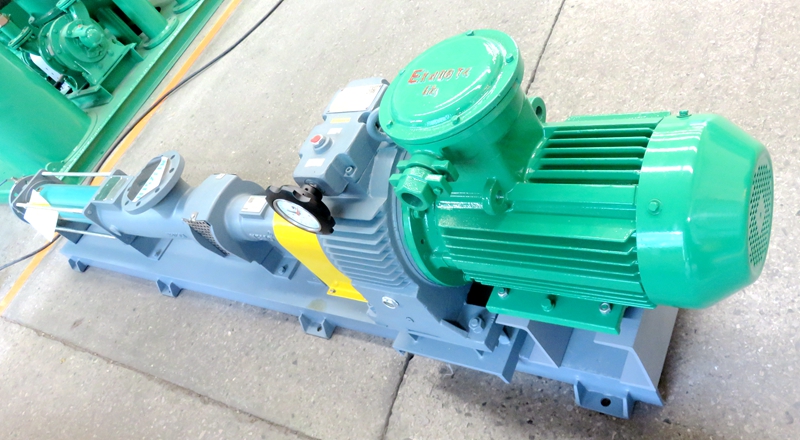

The centrifuge adopts the high-speed dewatering centrifuge of the purification system. This centrifuge is a special customized centrifuge that can treat both ordinary mud and waste mud. The flocculation system is also a specific flocculation system. 3 chemical agents can be added to meet Different needs of customers.

GN Solids Control’s mud purification system and sludge dewatering equipment have attracted much attention in the international market, word of mouth, and there are sufficient market cases in China. Shield engineering customers include China Railway Tunnel, China Railway Tunnel Two, China Railway 18th Bureau and China Railway Shield construction and mud treatment companies such as environmental engineering companies. Shield machine manufacturing supporting customers include China Railway Equipment, German Herrenknecht and other large shield machine equipment companies. The strong R&D and manufacturing capabilities and rich industry experience have won customers’ full trust.

GN Solids Control can also design and manufacture mud recovery systems according to customer requirements and provide constructive suggestions.

If you want to know more about GN Solids Control, we sincerely welcome you to inquire or visit our company.