Once a client asked some questions about drilling fluid systems, and I think it is very representative, so I just post here, for all your reference.

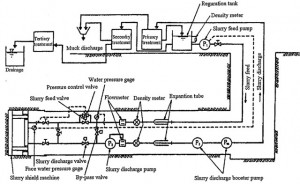

*How is the fluid transferred between compartments?

If you still confused by this, contact with our sales, maybe you need a more detailed drawing, or more contact.

*Is the coupling between the tanks rigid or flexible, what is the diameter?

Definitely yes

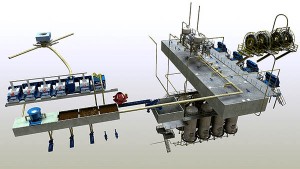

*Are the shakers, desilters, etc.. designed to be removed quickly for transport? Are they fitted to one large skid or individual units?

It depends sometimes, shakers, desilters are conected with the mount with screws. So if you need, it is easy.

*Can the mounting of the shakers, desilters etc.. be reversed if we require to place the tanks on the opposite side of the machine?

If you need, contact with our engineer firstly.

*For cleaning purposes, how are the tanks accessed, are the walkways removable?

Yes, the walkways is removable.

*I would prefer the hopper at ground level as all the fluids can be next to the hopper and it is easier to dispose the bags into a skip. Also in adverse weather conditions, it is easier to mix additives beneath a canopy away from the wind and rain which is something I’d like fitted.

Thank you very much for your information, and we can design the jet mud mixer as you required.

*Can you please provide a quote and specification for a degasser?

That is cool, we not only supply four phase soldis control equipments, and we also supply vacuum degasser, poor boy degasser, centrifugal pump, and shaker screens.

*What is the weight of the tanks with the components removed for transport?

You can find it in the quotation.

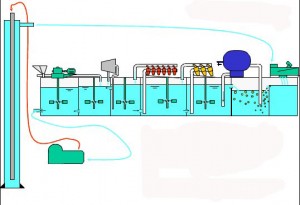

*The volume of each compartment?

It is different from systems one another.