Our customers are always asking questions like: Can I have your reference list? Are your products adapt to our situation? and so on… I konw what they really want to know: Why I choose GN Solids Control, and is there others used your products and do they satisfied with it?

Here we go!

Firstly, I will introduce you the principle of GN Solids Control: Only Top Quality Products! This is our promise!

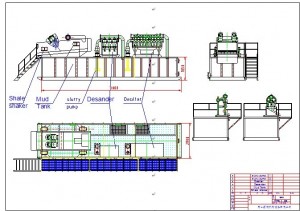

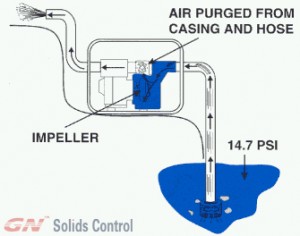

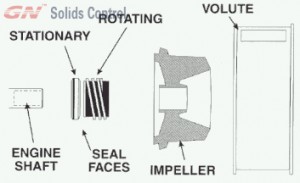

Secondly, GN Solids Control supply all the parts of solids control system, including shale shakers, desanders, desilters, mud tank separation, centrifugal pumps, decanting centrifuges and so on, and GN supply all the products right as you required.

Shale shaker,linear motion shaker

Drilling mud shale shaker manufacturer,linear motion shale shakers for drilling fluids,Solids control shale shaker,oilfield drilling cuttings linear motion …

Derrick Replacement 503 PMD shaker screen to Brazil

Twin drilling mud shale shaker and backup spare parts to Morocco

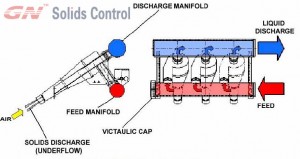

desander,hydrocyclone desander,China desander desilter manufacturer

Hydrocyclone desander manufacturer,oilfield desander with good cones,buy solids control drilling mud fluids desander from China supplier for sale.

desilter-hydrocyclone fluids desilter,drilling mud desilter

Hydrocyclone desilter manufacturer,drilling fluids desilter,mud desilter and desander with good cones,China oilfield solids control desilter supplier.

mud tank,drilling fluids tank,mud tanks design

Drilling Mud tank manufacturer,drilling fluids tanks customized design,design mud tanks for Oil Gas drilling and HDD Solids Control mud system.

Storage mud tank agitator to Thailand

Premix mud tank equipments and spare parts to Kazakstan

Drilling mud tank recycle systems equipments for Kazakhstan

Our customer is all over the world, as you can see, and click here to know more about GN news…