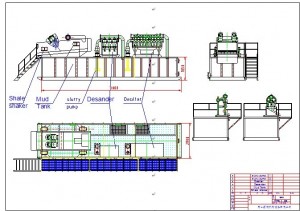

GN complete line machineries can be used for liquid and solids separation.

Below,you’ll see a machineries table which used For GN240 Liquid Solids Separation.

| Solids Liquid Separation Machineries | Capacity | Cut Point |

| 150YZ250-40B Slurry Pump | 240m³/h | Feeding Shale Shaker |

| GNZS150-3 Shale Shaker(40Mesh) | 240m³/h | ≥0.42mm |

| 150YZ250-40A Slurry Pump | 270m³/h | Feeding Desander |

| ZQJ250x3 Desander(10”) | 270m³/h | ≥0.07mm |

| 150YZ250-40A Slurry Pump | 270m³/h | Feeding Desilter |

| ZQJ100x18 Desilter(4”) | 270m³/h | ≥25microns |

Liquid Solids Separation Process

1. The 150YZ250-40B Slurry Pump Feed GNZS150-3 Shale Shaker from Slurry Pit.

2. In the first phase the Liquid and Solids passes over GNZS150-3 Shale shakers with 40mesh Screens to remove debris and larger particles. The debris can include: grass, roots, leaves, cans, plastic, rags and bottles. Solids Size≥0.41mm will be removed from the liquid

3. The Liquid with solids size≤0.41mm, with the above debris removed drops into an isolated section of the tank(Compartment 1) where it is picked up by a 150YZ250-40A Slurry Pump.

4. This 150YZ250-40A Slurry Pump. moves the slurry to the second phase, feed liquids with solids to ZQJ250x3 Desander(10” Cones).

5. Here the liquids with solids is pumped through the de-sanding Hydro-cyclones, which removes the solids above the 75 micron size.

6. The overflow from these hydro-cyclones drops into a second isolated tank section(Compartment 2), while the underflow is discharged from the trough of the ZQJ250x3 Desander. Continue reading