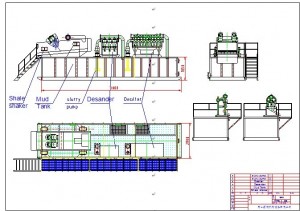

GN complete line machineries can be used for liquid and solids separation.

Below,you’ll see a machineries table which used For GN240 Liquid Solids Separation.

| Solids Liquid Separation Machineries | Capacity | Cut Point |

| 150YZ250-40B Slurry Pump | 240m³/h | Feeding Shale Shaker |

| GNZS150-3 Shale Shaker(40Mesh) | 240m³/h | ≥0.42mm |

| 150YZ250-40A Slurry Pump | 270m³/h | Feeding Desander |

| ZQJ250x3 Desander(10”) | 270m³/h | ≥0.07mm |

| 150YZ250-40A Slurry Pump | 270m³/h | Feeding Desilter |

| ZQJ100x18 Desilter(4”) | 270m³/h | ≥25microns |

Liquid Solids Separation Process

1. The 150YZ250-40B Slurry Pump Feed GNZS150-3 Shale Shaker from Slurry Pit.

2. In the first phase the Liquid and Solids passes over GNZS150-3 Shale shakers with 40mesh Screens to remove debris and larger particles. The debris can include: grass, roots, leaves, cans, plastic, rags and bottles. Solids Size≥0.41mm will be removed from the liquid

3. The Liquid with solids size≤0.41mm, with the above debris removed drops into an isolated section of the tank(Compartment 1) where it is picked up by a 150YZ250-40A Slurry Pump.

4. This 150YZ250-40A Slurry Pump. moves the slurry to the second phase, feed liquids with solids to ZQJ250x3 Desander(10” Cones).

5. Here the liquids with solids is pumped through the de-sanding Hydro-cyclones, which removes the solids above the 75 micron size.

6. The overflow from these hydro-cyclones drops into a second isolated tank section(Compartment 2), while the underflow is discharged from the trough of the ZQJ250x3 Desander.

7. The slurry, which now has solids removed above 75 microns is picked up from (Compartment 2) by a second 150YZ250-40A Slurry Pump. and pumped through a bank of de-silting hydro-cyclones on ZQJ100x18 Desilter(4” Cones). to remove the solids passed by the de-sanding hydro-cyclones. This phase removes solids down to the 25 micron size. Again the overflow from the de-silting hydrocyclones drops into the third tank section (Compartment 3),while the under flow is discharged from the trough of the ZQJ100x18 Desilter(4” Cones).

8. The now “cleaned” liquids is in the third tank section (Compartment 3).

9, If want to separate fine solids <25microns, the next phase can use centrifuge.