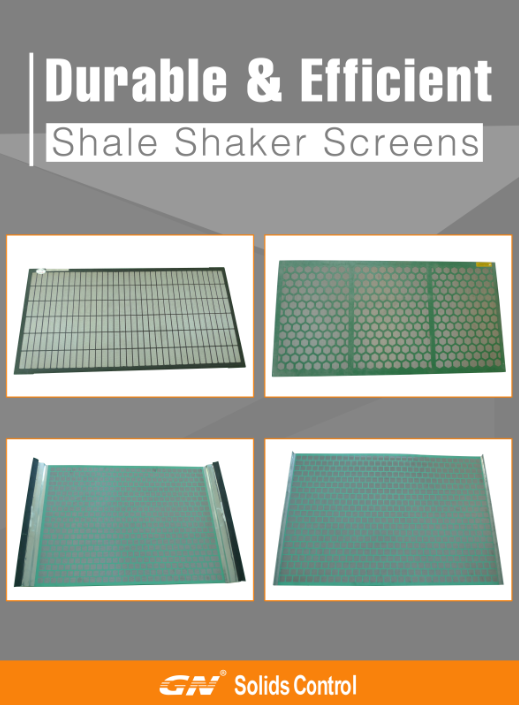

GN Solids Control is China & USA leading brand for shale shaker screens, as well as solids control & drilling waste management. With high quality and much better price, GN Shaker screen have replaced lots of original USA shaker screen, saving much cost for clients and also giving better user experience.

1) What shaker screen you can get from GN ?

Replacement shaker screen for Derrick FLC500 shaker, Derrick FLC2000 shaker.

Replacement shaker screen for NOV brandt king cobra shaker

Replacement shaker screen for MI Swaco Mongoose shaker

Replacement shaker screen for FSI5000 shaker

Replacement shaker screen for Scomi shaker

……

2) What support you can get from GN?

For large order, we can offer some screen sample for test first. After the end user / drilling company accept the quality, we can sign the purchase order in large quantity.

We also welcome client to check GN shaker screen production line close to Beijing, China. We are very close to Beijing International Airport, can arrange car for visitor, pick up from the airport, arrange hotel and drive back to the airport after visiting.

We have a separate specialized factory for shaker screen production. The visitor can check the raw material for production, the process machines, and the hot press craft, package etc.

3) GN product range

GN Solids can offer the complete line of solids control equipment, drilling waste management, mud system etc.. Pls check below GN product range:

Solids control equipment: shale shaker, mud cleaner, decanter centrifuge , agitator, centrifugal pump, shear pump, mud tank etc.

Drilling waste management equipment: vertical cuttings dryer, solidification unit, screw conveyor, slurry pump, screw pump, thermal desorption unit.

Mud system: oil drilling mud system, HDD compact 500gpm mud system, mining/piling desanding plant, liquid mud plant, slurry separation plant etc.

Industry centrifuges, like big bowl centrifuge for TBM, FHD centrifuge for higher standard application.