GN Solids Control is a professional manufacturer of drilling mud solids control equipment. It currently produces equipment in more than 70 countries and regions around the world, providing drilling solids control equipment for dozens of oilfield service providers around the world. The after-sales service has a global radius, responding 24 hours a day to customers around the world, and fulfilling the after-sales service commitment within 72 hours. Four important branch structures have been established around the world, with the United States, Russia, Dubai, and North Africa as parts supply and after-sales services.

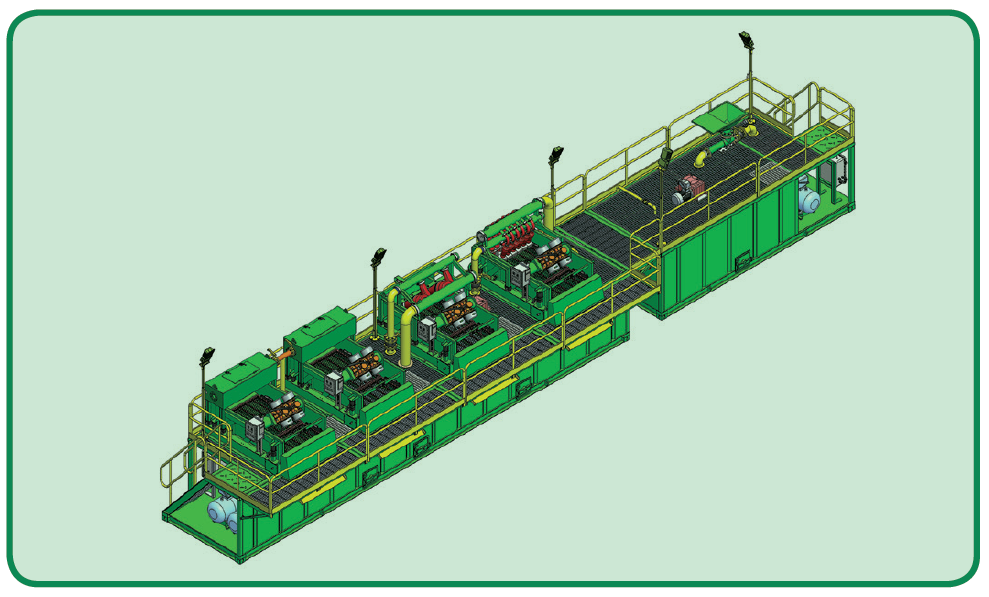

The following is a very simple and practical mud mixing system:

System components:

- Armoured mud tank device: size 8000*2600*2200mm, volume 20 cubic meters, armored design for transportation and hoisting and mobile construction projects. The round mud mixing tank has no dead angle design, the mud is evenly stirred, and the mud condition is beneficial to the drilling construction service. It includes convenient design such as ladders, walkways, guardrails, manifolds and valves.

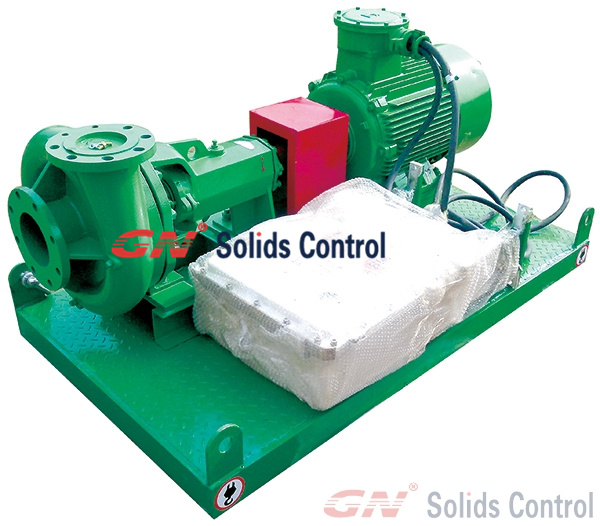

- Mud transfer pump: GNSB6*5C-13J, motor power 45kw, conveying capacity 150 cubic meters / hour. The main purpose is to transport the mud to carry the mud material in the funnel into the mixing tank.

- Mixing hopper: GNSLS045A, mainly used for adding dry powder mud materials.

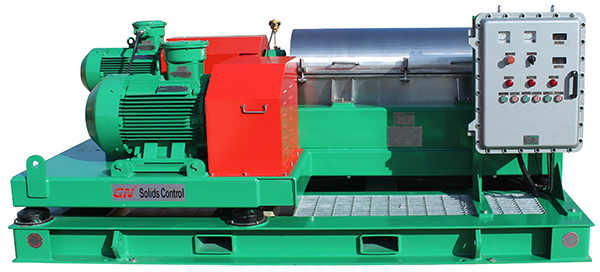

4. mud agitator: GNJBQ075DD, motor power 7.5kw, speed 60 rev / min, double impeller, mainly the mixing and miscibility of the dry powder slurry material and water.

- Electronic control system: It is mainly to control the explosion-proof control system of the above equipment that needs mud mixing work.

In the drilling environment, the uniformity of the mud will greatly affect the drilling work. In order to ensure the mud supply flow and quality, the mud mixing should be taken seriously.

More question,welcome contact GN solids control