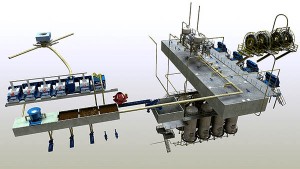

Bottom type mud guns are the drilling mud gun installed close to the bottom of the tank which are meant to provide supplemental or primary mixing in mud tanks depending on the number being used and the pit size. They are best used in tank corners to keep solids from settling and a mud agitator is placed in the tank center.Bottom Type Mud Guns are designed for submerged service in steel pits.

Specification of GN Bottom Type Mud Guns

NJQ Series Mud GunTechnical Parameters

| Model | GNNJQ50-3 | GNNJQ80-3 |

| Diameter | 2"(φ50) | 3”(φ80) |

| Valve ID&pressure | 50mm/3.2MPa | 80mm/3.2MPa |

| Interface size | 2" | 3" |

| Work Pressure | ≤1.6MPa | ≤1.6MPa |

| Nozzle number | 3 | 3 |

| Rotation angle | 120° | 120° |

| Remarks | Rotation availaible |

GN Solids Control is one of the top mud gun manufacturers in China,and with sales and services around the world.

Bottom Type Mud guns are to be located in the tank corners. The centerline of the nozzle is to be located about 6” off the tank bottom.