Closed loop drilling fluids system (sometimes referred to as closed mud or pitless system)are system which do not need mud pits, which can greatly reduce or eliminate the discharge of toxic drilling wastes on site.

What mud systems need mud pits?

1 HDD mud system need mud pits, the drilling mud flow to mud pit, and the slurry pump installed into the mud pit transfer the mud to HDD mud cleaning system, and the processed mud is pumped to the rig again.

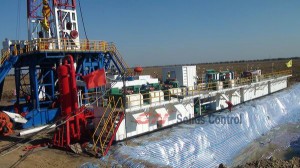

2 At a typical oil & gas drilling site, drilling fluids are circulated through the wellbore, then the fluids and drill cuttings are deposited in a reserve pit dug near well. This pit is used to hold used drilling fluids and wastes. There are many potential problems from pits — leaky liners and overflows can lead to soil and water contamination, pits can produce odors and toxic air contaminants, and pits can be a hazard for birds and wildlife.