GN solids control has designed and exported many sets of 1000HP land rig solids control system to worldwide clients for oilfield drilling, we have many existing design for their different requirement. Several clients called it “mud handling system”, “mud tank system”.

GN 1000HP land rig solids control system is including the following equipments:

1 Linear motion shale shaker or BEM shaker 2 sets, they can be made of dual tandem shaker

2 vacuum degasser with 1200gpm or 1600gpm treating capacity

3 Linear motion or BEM mud cleaner with 55KW centrifugal pump

4 high speed decanter centrifuge 1 set or middle speed decanter centrifuge 1 set, depends on budget

5 Twin Jet mixing unit with 2pcs mixing pump, max mixing rate can reach 200kg/min if they work at the same time

6 poor boy degasser with 1000gpm flow rate

7 Flare ignition device

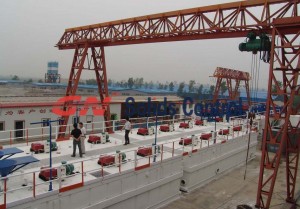

8 Mud tanks: including shaker tank, settling tank, suction tank & reserve tank, water tank, fire tank, pill tank, trip tank, etc.

9 A complete set of electric control system, explosion proof grade IP56, other electric specs and explosion proof class are available.

Once we get the rig layout, we can arrange for the layout of mud tank system and submit process flow drawing and layout drawing of the solids control system. Our design may take the following aspects into consideration.

1 waste solids discharge: we will try our best to simple the solids discharge operation, and save land area of solids discharge, sometimes a screw conveyor is applied to keep the mud system in compact structure and convenience solids discharge.

2 transportation convenience:

All the handrail and walkway are foldable and can be moved together with tank body, you do not need to disassembly it.

All the equipments and tanks are designed into standard transportation dimension, it can meet transportation limit in any country, it less the movement cost effectively.

3 Maintenance cost minimum

We apply top brand components and material, which are wear and do not need to replace continually, one the other hand, it saved drilling time.

For more information, pls contact GN sales.