HDD means horizontal directional drilling or Directional boring, is a steerable trenchless method of installing underground pipes, conduits and cables in a shallow arc along a prescribed bore path by using a surface-launched drilling rig, with minimal impact on the surrounding area.

Drilling fluids have several important functions. They cool and lubricate the drill bit, stem and other down hole tools. The fluid also assists in sealing the sides of the bore, therefore stabilizing the borehole. Finally, drilling fluids are designed to carry the cuttings out of the hole.

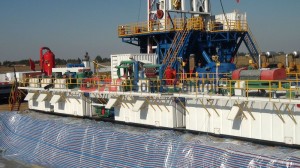

The most widely used drilling fluids for HDD applications are bentonite, even if they are not so expensive compared with oilfield drilling fluids, but it is still a pollution for the environment, especially usually they dig a mud pit for HDD and pump the drilling fluids from the mud pit to shale shaker. After the directional boring, how to treat the used drilling mud become a problem.