Mud recycling system is important in hdd boring, how mud travels in hdd no dig system, is always a problem people may ask. And then, we concern what GN Solids Control can supply, and who all over the world have chosen GN.

How mud travels in hdd no dig system

The mud is born clean, it was mixed by bentonite and some chemical mixtures, then stored by a tank. Ready to go to the hdd no dig system. Then it was pumped to the pipe and to boring the hole, later it was bring back by the pipe to a storage tank with all the  cuttings rocks and sands.

cuttings rocks and sands.

The mud recycling is needed now, the drilling mud with sands and drilling cuttings are pumped to the system, then the cleaned mud return to the pipe.

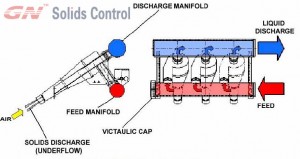

The mud recycling is usually including shale shaker, mud cleaner, or desander and desilter instead, sometimes decanter centrifuge is also needed. The drilling mud flow through the shale shaker, desander cones, desilter cones, then the decanting centrifuge.

All units within the range use two processes when cleaning mud to ensure the drilling fluid can be recycled and used to the efficiency of the first time it is pumped down the hole.

The first process is with the use of a shaker screen. When the mud is drawn from the hole it is first discharged onto a fine mesh, which constantly moves from side to side spreading the mixture across it. This allow the drilling fluid to fall through whilst larger items such as rocks and cutting remain on the mesh until they are shaken off its bottom edge and removed from the system. Continue reading “mud recycling system for hdd boring”