1. Source analysis of oily sewage

The sources of oily sewage are very extensive. Oily sewage is generated in the processes of steel refining, industrial production, oil extraction, pesticide and food processing and production, and these oily pollutants mainly exist in four forms, respectively It is dissolved oil, dispersed oil, slick oil and emulsified oil.

Petrochemical industry. In the petrochemical industry, oily wastewater will be generated at almost any stage from the initial extraction to the final transportation and consumption. With the rapid development of China’s science and technology, China’s tertiary oil recovery technology has also been widely used. Improved the oil displacement effect, but also made the composition of sewage more complicated.

Chemical and pharmaceutical engineering. The main source is oily wastewater from high-concentration processes. During the manufacturing process, a large amount of water and lubricating oil are used in the stages of raw material reaction, product separation and raw material pretreatment, so a large amount of oily wastewater will be produced in the later stage.

Metal smelting industry. In the process of metal smelting, whether it is the material in contact with oil or the equipment in contact with oil, we need to cool, clean and lubricate it, and the lubricating oil may directly contact with it, so it will form oily sewage .

Food processing and production. In the process of food processing and production in our country, oily sewage is generated during equipment cleaning and machine lubrication.

GN Solids Control is one of the few manufacturing companies with experience in oily sludge treatment plants at home and abroad. Our processing equipment has passed the verification of many practical applications on site and has been widely recognized by customers. It can meet the treatment of most oily sludge, better recover oil and water, and reduce the cost of solid waste treatment.

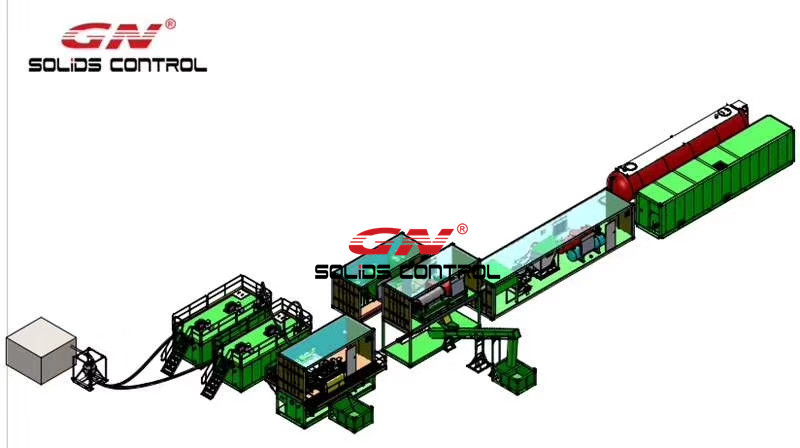

Oily sludge refers to a mixture of oil, water and solids. In order to treat sludge and recover oil and water, oil, water and solids must be separated. At the same time, how to dispose of solids at a lower cost and recover as much oil as possible is very important. GN Solids Control oily sludge treatment complete equipment, including centrifuge, shale shaker, chemical dosing unit, through chemical hot washing, and then through multi-stage separation, and finally obtain clean oil and water, and low oil content solids. The recovered oil can be sold to refineries, and the water can be repeatedly hot washed. The oil content of the separated solid phase material can be as low as 2%, and finally it can be pyrolysis or biodegradation to achieve harmless treatment requirements.

More question, welcome contact GN Solids Control