GN–CONSTRUCTION–MUD–AND–WATER–SEPARATION–SYSTEM–SOLD–TO–NEW–ZEALAND

GN is a well-known brand from China, its full company name is HeiBei GN Solids Control Co.,Ltd which locadted in No.3 Industry Road, Dachang Chaobai River Development Area,Langfang, China; We are known around the world for unique innovation without compromise, sophistication while maintaining user simplicity, and superb service to our extremely wide customer base.specializing in supplying solids control& waste management equipment to the global market,

This big system mainly consists of 5 module.

Coarse Mining Shaker Introduction-Module 1.

The term “coarse mining shaker” typically refers to a piece of equipment used in the mining industry for separating and sorting materials. These shakers are often part of a larger system designed to separate mined materials based on size, weight, or other characteristics.

In mining operations, shakers are commonly used in conjunction with screens to separate materials of different sizes. They work by shaking or vibrating the material, allowing smaller particles to fall through the screen while larger particles are retained for further processing.

The specific design and function of a coarse mining shaker can vary depending on the type of material being processed and the requirements of the mining operation. If you have more specific questions about coarse mining shakers or their applications, feel free to provide additional details, and I can offer more targeted information.

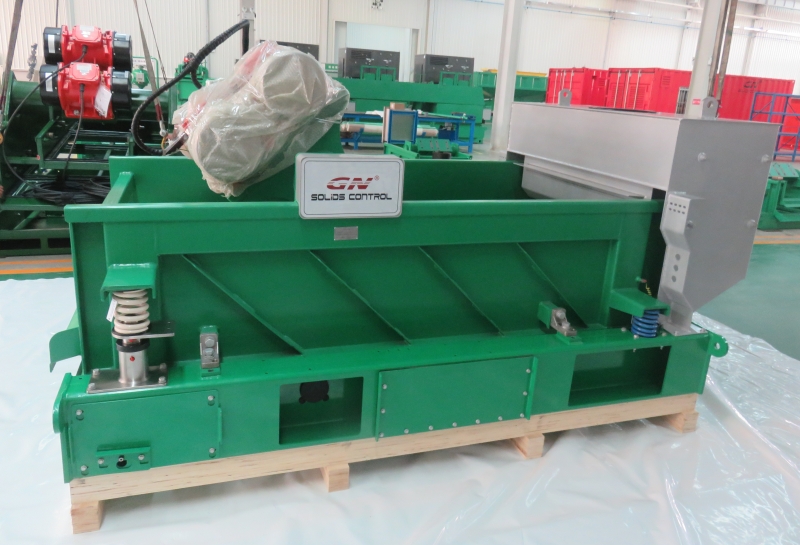

Double Deck Shale Shaker Introduction-Module 2.

A double deck shale shaker is a specific type of shaker equipment used in the oil and gas industry, particularly in the process of drilling for oil and gas. Shale shakers are a crucial component of the solids control system, which is used to separate solid materials (such as cuttings) from the drilling fluid.

The “double deck” design means that the shale shaker has two levels or decks for processing the drilling fluid. This allows for more efficient and effective separation of solids from the drilling fluid. The first deck typically handles the coarse solids separation, while the second deck further processes the fluid to remove finer solids.

The shale shaker operates by using a series of screens with different mesh sizes to separate the solid particles from the drilling fluid. The vibrating motion of the shaker helps to convey the solids up the screen, while the fluid passes through the screens and is collected for further use in the drilling process.

Overall, the double deck shale shaker plays a critical role in maintaining the quality of the drilling fluid by removing unwanted solids, which in turn helps to protect drilling equipment and ensure efficient drilling operations.

Desilter Introduction-Module 3.

A desilter is a piece of equipment used in the process of drilling for oil and gas. It is part of the solids control system, which is responsible for removing solid particles from the drilling fluid to maintain its properties and ensure efficient drilling operations.

Specifically, a desilter is designed to remove fine solid particles, typically in the range of 15 to 44 microns, from the drilling fluid. It accomplishes this by using a set of hydrocyclones, which are cone-shaped devices that utilize centrifugal force to separate the solids from the liquid. The desilter is positioned downstream of the shale shaker and the desander in the solids control system.

The drilling fluid, also known as drilling mud, enters the desilter, where it is directed into the hydrocyclones. As the fluid passes through the hydrocyclones, the centrifugal force causes the solid particles to separate from the liquid and accumulate at the bottom of the hydrocyclones. The clean drilling fluid is then discharged from the top of the hydrocyclones and returned to the active system for reuse in the drilling process.

By removing fine solid particles, the desilter helps to maintain the properties of the drilling fluid, such as its viscosity and density, and ensures that the fluid can effectively carry cuttings to the surface during the drilling process.

Desilters are an important component of the solids control system, contributing to the overall efficiency and success of drilling operations in the oil and gas industry.

Decanter centrifuge-Module 4.

A decanter centrifuge is a specialized centrifugal processing device used in various industries, including the oil and gas sector, wastewater treatment, food and beverage, and chemical processing. In the context of the oil and gas industry, decanter centrifuges play a crucial role in the separation and clarification of liquid and solid phases in drilling operations and in the processing of crude oil.

Dosing flocculation-Module 5.

-

Dosing:

- Dosing involves the controlled addition of chemical substances, such as coagulants and flocculants, to the water being treated. These chemicals are added in specific quantities to facilitate the removal of impurities and the clarification of the water.

-

Flocculation:

- Flocculation is a physical and chemical process where destabilized particles in the water form larger, floc-like aggregates. These aggregates are easier to remove through sedimentation or filtration processes.

When these two processes are combined, it’s often referred to as “dosing and flocculation.”

In the context of the oil and gas industry, dosing and flocculation processes might also be used in the treatment of produced water or in the clarification of drilling mud as part of the overall water management and solids control system.

For our equipment brochure or more info, please visit our unique official website: www.gnsolidscontrol.com

MichaelSong

Sales manager

E: michael@gnsolidscontrol.co/michael@gnsolidscontrol.com