GN is a well-known brand from China, its full company name is HeiBei GN Solids Control Co.,Ltd which locadted in No.3 Industry Road, Dachang Chaobai River Development Area,Langfang, China; We are known around the world for unique innovation without compromise, sophistication while maintaining user simplicity, and superb service to our extremely wide customer base.specializing in supplying solids control& waste management equipment to the global market.

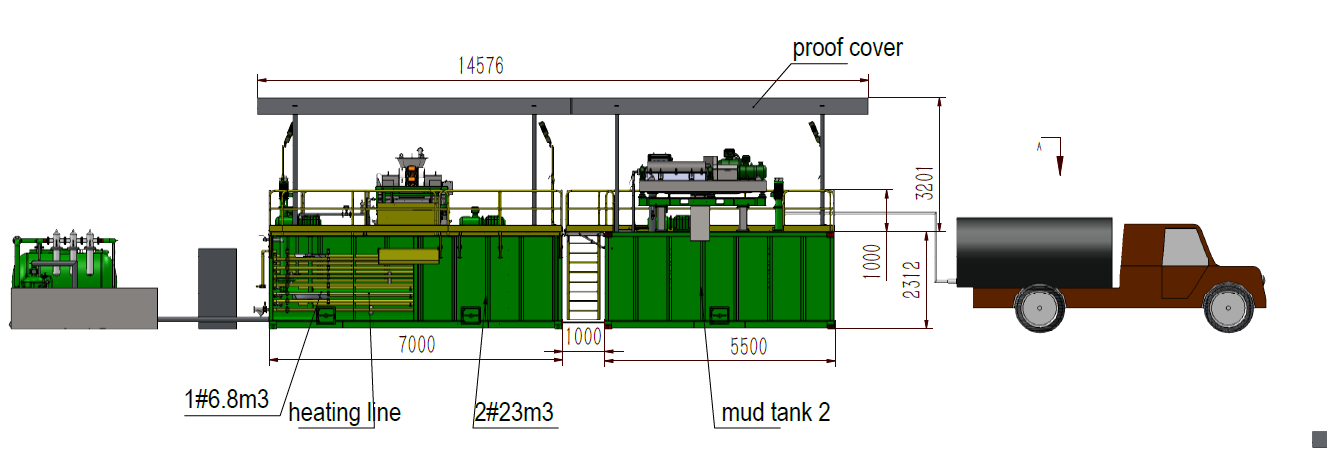

A Mud Fluid Treatment System is a crucial component in the drilling operations. It manages and processes the drilling fluids, commonly known as “mud,” used to lubricate and cool the drill bit, transport cuttings to the surface, and maintain hydrostatic pressure to prevent well blowouts.

Key Components of a Mud Fluid Treatment System:

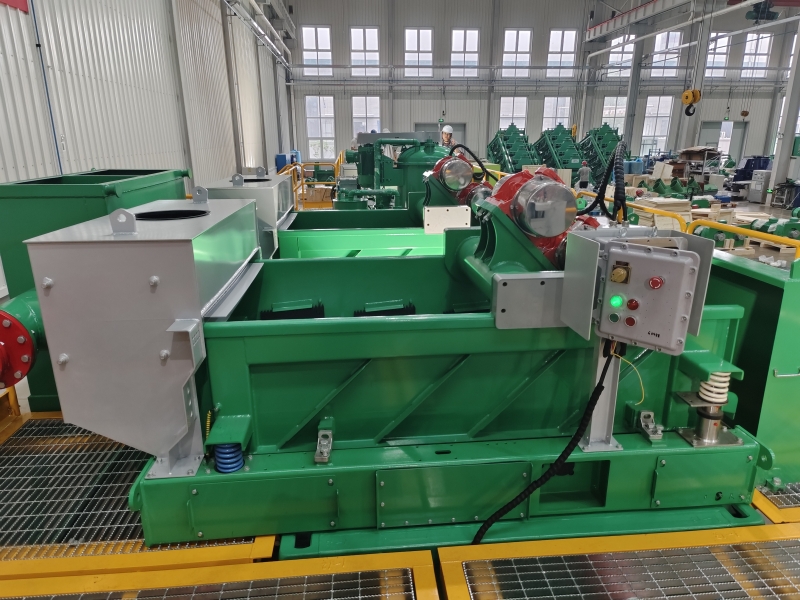

- Shale Shakers: The first step in the treatment process, where large solid particles (cuttings) are removed from the drilling fluid. The fluid is passed over vibrating screens that separate the solids.

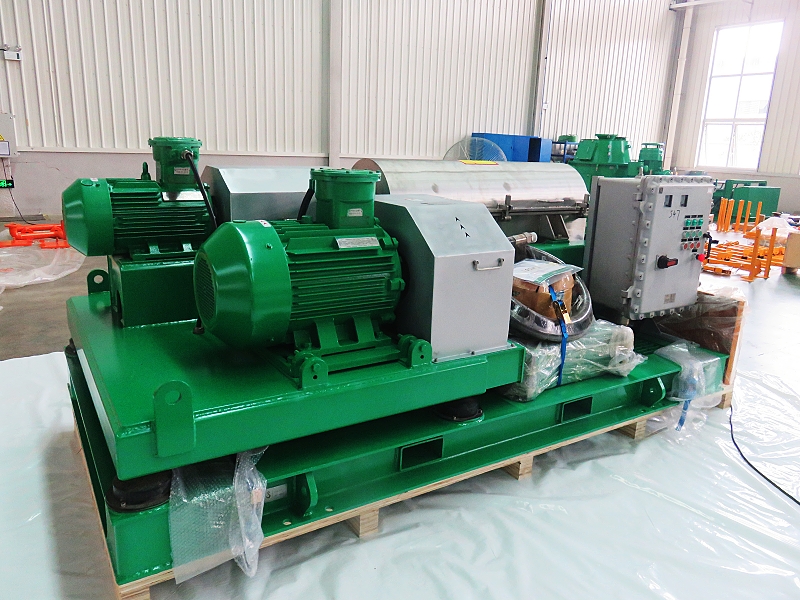

- Desander and Desilter: These devices remove finer particles from the drilling fluid. Desanders target particles larger than 40 microns, while desilters focus on particles larger than 20 microns.

- Mud Tanks: Storage units for drilling fluids. These tanks hold the treated mud before it is recirculated back into the well.

- Mixing Hoppers: Devices used to add chemicals and other additives to the drilling fluid to maintain its desired properties.

- Pumps: Circulate the drilling fluid through the system and back into the well.

Functions of the Mud Fluid Treatment System:

- Solid Control: Efficiently removing drill cuttings and other solids to keep the mud’s properties within the desired range.

- Mud Recycling: Ensures that the treated mud can be reused, reducing waste and minimizing environmental impact.

- Hydrostatic Pressure Management: Maintains the correct mud weight to prevent well blowouts and other drilling issues.

- Cooling and Lubrication: Keeps the drill bit cool and lubricated, enhancing its lifespan and effectiveness.

A well-designed mud fluid treatment system is essential for efficient and safe drilling operations.

Here are some of the key benefits:

1. Enhanced Drilling Efficiency

- Improved Rate of Penetration (ROP): By effectively removing cuttings and maintaining optimal mud properties, the system ensures that the drill bit operates more efficiently, increasing the rate of penetration and reducing drilling time.

2. Cost Reduction

- Reduced Mud Consumption: By recycling and treating the drilling fluid, the system minimizes the need for fresh mud, leading to significant cost savings on drilling fluid expenses.

- Lower Waste Disposal Costs: Efficient solid control and treatment reduce the volume of waste that needs to be disposed of, cutting down on disposal costs.

3. Environmental Protection

- Minimized Environmental Impact: Recycling drilling fluid reduces the volume of waste and the need for new fluid, minimizing the environmental footprint of drilling operations.

- Cleaner Discharge: The system ensures that any discharged fluid meets environmental standards, protecting surrounding ecosystems.

4. Safety Enhancement

- Pressure Control: By maintaining the correct mud weight, the system helps prevent dangerous situations like well blowouts, enhancing the overall safety of the drilling operation.

- Gas Management: The degassing process removes hazardous gases from the drilling fluid, reducing the risk of gas-related incidents.

5. Improved Wellbore Stability

- Consistent Mud Properties: The system ensures that the drilling fluid maintains its properties, such as viscosity and density, which are crucial for stabilizing the wellbore and preventing issues like borehole collapse.

6. Extended Equipment Life

- Reduced Wear and Tear: Clean drilling fluid, free from abrasive solids, reduces wear on the drill bit and other drilling equipment, extending their operational life and reducing maintenance costs.

7. Better Data Quality

- Accurate Logging: With cleaner drilling fluid, the quality of data obtained from mud logging and other monitoring activities improves, leading to more accurate assessments of the formation being drilled.

8. Operational Flexibility

- Adaptability to Various Conditions: The system can be adjusted to handle different types of drilling environments, from shallow to deep wells, and different mud compositions, providing operational flexibility.

For our equipment brochure or more info, please visit our unique official website: www.gnsolidscontrol.com

MichaelSong

Sales manager

Whatsapp:+86 17801799913