GN NEWS UPDATE: 4–SETS–OF–SOLID–CONTROL–SYSTEM–DESANDERS–FOR–DRILLING–RIGS–WERE–SOLD–TO–THE–INDONESIAN–PROJECT

GN is a well-known brand from China, its full company name is HeiBei GN Solids Control Co.,Ltd which locadted in No.3 Industry Road, Dachang Chaobai River Development Area,Langfang, China; We are known around the world for unique innovation without compromise, sophistication while maintaining user simplicity, and superb service to our extremely wide customer base.specializing in supplying solids control& waste management equipment to the global market.

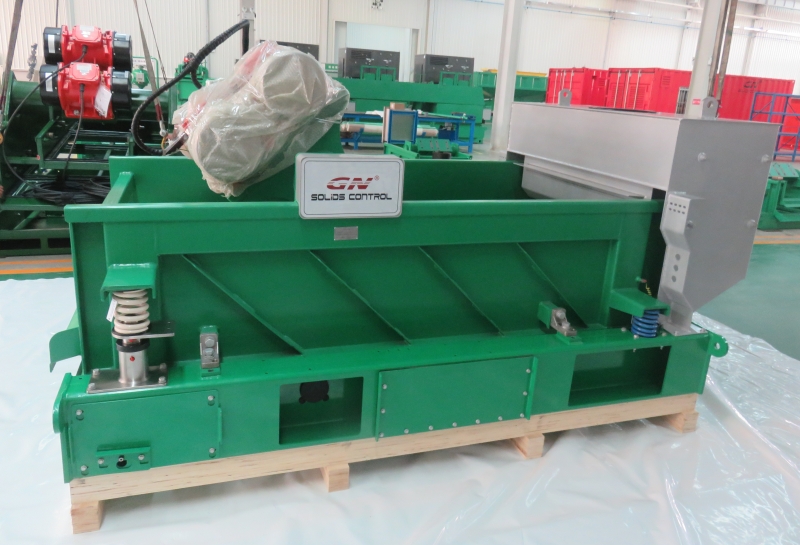

GN Shale Shaker

One Deck and Two Deck Shale Shaker manufactured by GN, Its screen area ranges from Min 1.35㎡ to Max 5.53㎡ suitable capacity 200GPM to 620GPM.

One Deck shale shaker wildely-used in OBM industry, mostly saw in oil and gas offshore drilling platform, ordered from heavy customer like PetroChina, Sinopec, CNOOC,etc. The motor has been choosing famous brand, like Oli (ltaly), Where the shale shaker is, there will be shaker screens.

GN is the only one manufacturer in China supplying all series shaker screen according to API RP 13C and API Q1 for the past 13 years until now.pecialize in separation equipment, include solids control equipment, industry decanter centrifuge, waste management equipment, and shaker screens.GN was established in 2007,and GN is the first API certified solids control equipment manufacturer from China, and GN products have been exported to over 60 countries around the world.

Our frame compostie shaker screen has been popular in the international market, order from heavy customer like Bake Huges,Total,etc.The steel frame had been welded by automatic robot which can avoid weld weaknesss as much as possible meanwhile,to bring more steady once continuous operation on site.

Except for our composite frame shaker screen, as one 15-year manufacturer in oil&gas industry, definitely yes, most replacement brand screen also supplied,like Derrick, Swaco,Kemtron,etc.

GN Desander

Desander is a device used to separate solid particles from fluids. In the oil and gas industry, especially during drilling, sand collectors are often used to remove solid particles such as sand, mud, etc. from drilling fluids. This helps protect drilling equipment and reduce wear on drilling pipes and equipment, while also helping to maintain drilling fluid performance and quality.

Sand collectors usually use centrifugal force or screens to separate solid particles. As the drilling fluid passes through the sand collector, the solid particles are separated and the clean drilling fluid is sent back to the drilling system for use.

Sand collectors play an important role in drilling operations as they help ensure the quality of drilling fluids, extend the life of equipment, and increase the efficiency of drilling operations.

GN Desilter

Desilter is a device used to separate and remove fine solid particles in drilling fluids. In oil and gas drilling operations, deslimers are often used to treat drilling fluids and remove tiny particles such as mud and clay to maintain the performance and quality of the drilling fluid.

Deslimers typically use centrifugal force to separate fine solid particles. As the drilling fluid passes through the deslimer, centrifugal force separates the tiny solid particles, and the clean drilling fluid is transported back to the drilling system for use.

Desanders are usually used together with desanders to ensure that various solid particles in the drilling fluid can be effectively removed. This helps protect drilling equipment, extend equipment life, and make drilling operations more efficient.

For our equipment brochure or more info, please visit our unique official website: www.gnsolidscontrol.com

MichaelSong

Sales manager

Whatsapp:+8617801799913

E: michael@gnsolidscontrol.co/michael@gnsolidscontrol.com