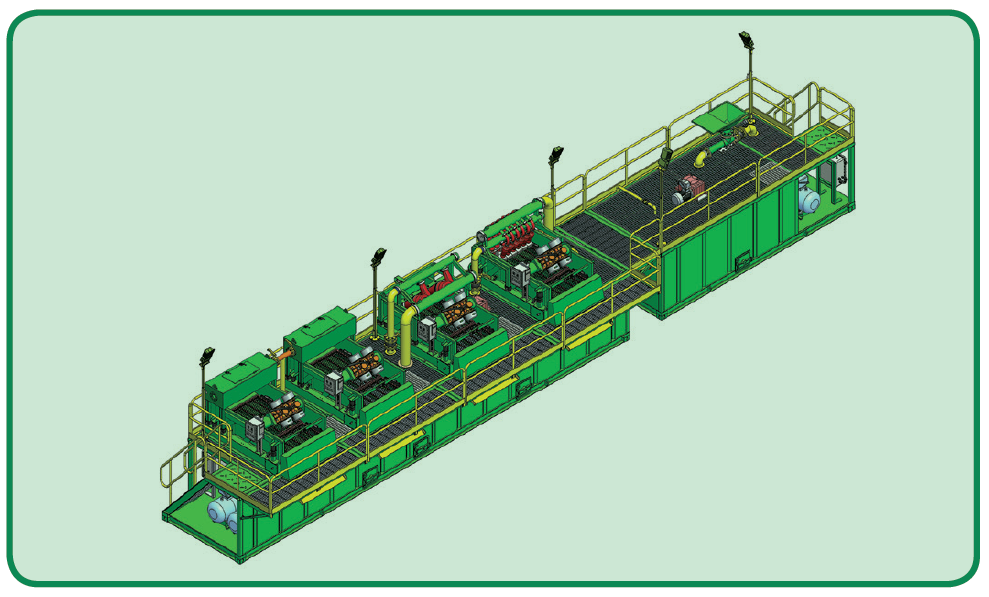

Drilling fluid was necessary for oil&gas drilling system,in some big HDD/TBM system,it was needed too

For the mud system’s design we need consider item as below:

1.hydrocyclone(desander/desliter)

When particle running at tydrocyclone,it will damage inwall of cone,normally the desander/desilter was made my metal material like gray iron or stainless steel,is hard enough,but service life will be short when treating some special mud,and fall off metal will effect density of mud,not suitable for some project

GN choose high quality PU material desander/desilter,to keep unit’s service life long enough,and keep mud’s state well

2.fluid surcafe balance

Most tank in solids control is top open design,the mud will freely move when overflow,GN have negative direction overflow design,untreated mud can’t move into clean mud,keep drilling work stable

3.cutting point

In some mini mud system,we will choose double deck shaker for solids control,the mesh’s choose was not like regular compound mode,the top deck need treat mud after hydrocyclone,the size should be small,the bottom deck is for untreated mud,size was bigger

4.total capacity

The mud cleaner can treat most mud and same tank’s top space,but in some condition,the solids part will carry more fluid after cleaner,because of not enough screen area,so in some deep drilling system,The desander and desiliter shoud install in different shaker,to keep treated solids more dry

5.tank volume

Some big dproject will need more fluid to support drilling,we will design longer storage tank,but with volume raise,the agitator/mud gun’s choose should be more,to keep mud mixing enough,like agitator’s impellar quantity will be 2,mud gun’s connect size should raise ,make mix power enough

GN will keep develop mud system,to bring better product for client