Mud cleaner is a combination of shale shaker, desander, desilter for oilfield drilling mud system, NOV Brandt also called it mud conditioner. There are many suppliers for mud cleaners, Derrick, MI-SWACO, Brandt, GN Solids Control, here we will make a comparison of the 4 model of mud cleaners. Take 1000gpm unit for example:

1 Derrick Mud Cleaner Features:

A round desilter manifold and/or a desander manifold is mounted in a cone discharge collection pan installed over the vibrating screen.Underflow from the hydrocyclones is received by the collection pan, which may feed directly to discharge or onto the vibrating screens for additional processing.

Derrick’s standard desander cone and desilter cone is 10” & 4”

2 MI-SWACO Mud Cleaner features:

Low profile through

Bypass intergral

Vertical installation method of desilter cone

MI-SWACO’s standard desander cone and desilter cone is 12” and 4”

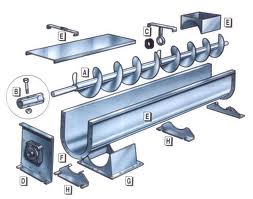

3 Brandt Mud Cleaner

Patented pin-and-hole screen securing system

Brandt’s standard desander cone and desilter cone is 10” or 12” and 4”

4 GN Mud Cleaner

Small footprint, compact design; desilter cone is installed vertical but inclined, GN standard desander cone and desilter cone is also 10 inch and 4 inch, which is same with Derrick’s.

GN mud cleane is convenient to ship it by containers, GNZJ703-2S12N(1000gpm) footprint is only 2403x1883x2195mm, but same treating capacity, Brandt Cobra 16/2 Mud Conditioner dimension is 2692 mm x 2032 mm x 2565 mm. For same treating capacity and function equivalent, GN mud cleaner is with the smallest size.