GN solids control supply vacuum pump,have some advice for the pump user

Vacuum pump is a new way for transfer material like sludge or slurry,compare with auger(screw conveyor),the vacuum transfer pump can save more space and make transfer work more clean

The pump is without any rotation items. With special structure design and powerful suction capability, it can be used at tough environmental for solids transfer

The vacuum pump is not work alone,it need air compressor to feed the pump

Normally vacuum pump will have minimum request for air compressor, like 17mm³/min(600CFM) at 550Kpa-795Kpa(80-114PSI),it means advice user prepare air compressor can fit this air demand and pressure,or higher,then the vacuum pump can work stable

The transfer/discharge distance is not fixed,it will change based on different material,transfer material should have enough flowability,can’t make pipe block and poor flowability means shorder distance vacuum can transfer,normally the manufacture will test transfer distance by clean water,and mark MDD(maximum discharge distance),higher capacity air compressor can make MDD longer

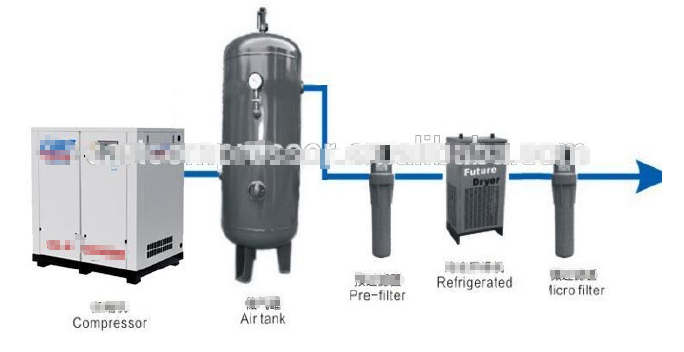

The compressor will include 5 parts,then to feed pump:

1.Main compressor

2.Air tank

3.Pre-filter

4.Refrigerated

5.Micro-filter

Some manufacture will supply main compressor signally,so,please mention to get all 5 part,then the vacuum pump can running

The vacuum pump can transfer waste mud/solids,drilling fluid,or hazardous waste recovery,for oil sludge in tank bottom clean,even sand course,fine,conventional and frac sand is supported

More use way of vacuum pump,please contact GN solids control