Recently, the sewage treatment centrifuge equipment produced by GN Solids Control has undergone rigorous testing in the factory and is ready to be loaded and shipped to the Yunnan customer project.

Many orders of GN Solids Control come from repeat orders from regular customers. I believe that the stable quality and outstanding performance of GN Solids Control products can give customers a strong confidence in GN Solids Control products.

So what are the characteristics of GN Solids Control equipment that can stand out among many domestic solid control counterparts? The following highlights the unique features of GN Solids Control sewage treatment centrifuge products:

Advantages and characteristics of GN Solids Control brand decanter centrifuge:

1. Drum material: duplex stainless steel 2304; screw pusher: duplex stainless steel 2205;

2. The main bearing is lubricated with dilute oil, the bearing runs better, can reach higher speeds, and is equipped with a lubrication protection system, which can still provide lubrication for 5-10 minutes after a sudden power failure;

3. Larger aspect ratio (4.2:1) and deeper liquid pool depth means better treatment effect and larger treatment capacity;

4. According to the nature and concentration of materials, use motors and differentials of different powers. (554EP adopts high differential speed, high-power motors ensure processing capacity; 554EC and EY use large speed ratios and small differential speeds, and low-power motors are more energy-efficient. );

5. A shock absorber is installed under the motor to avoid the impact of vibration between the motor and the centrifuge host;

6. The upper cover of the collection box adopts a double-layer structure and is lined with soundproof cotton, which reduces the noise of the centrifuge;

7. The collection box is equipped with a flushing pipe, so customers can flush the collection box even more;

8. Equipped with scrapers and end scrapers to prevent solid wear and tear, and a slag retaining ring to prevent material blocking on the solid phase side of the collection box;

9. Three kinds of centrifuges, three different angles, three different pitches, and BD plates with corresponding diameters can be designed according to different material concentrations to achieve better processing effects;

10. For the materials with high solid content and easy to cause wear, EP centrifuges have added slag discharge wear resistant wear sleeves, slurry outlet wear resistant sleeves, and wear-resistant alloy sheets are inlaid on the screw pusher, while EC The CY centrifuge mainly handles materials with low solid content and not easy to cause abrasion, and wear-resistant alloys are spray-welded on the liquid outlet and spiral blades;

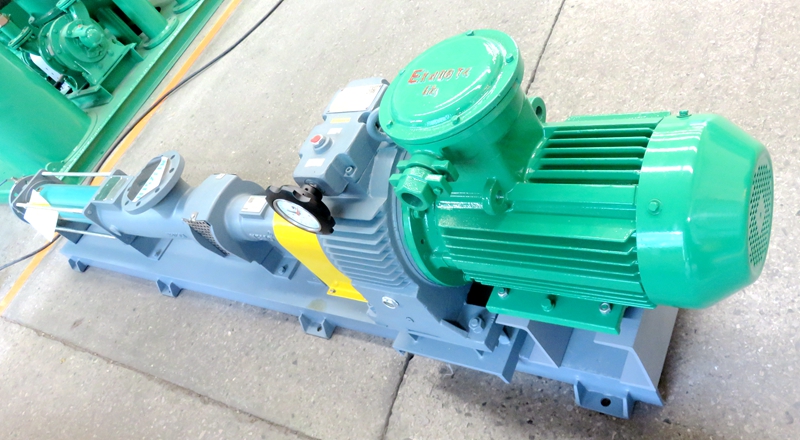

11. Supporting special screw feed pump for slurry supply to ensure stable flow and avoid blockage failure

If you are interested about our product, welcome contact us