Screw conveyors, sometimes called augers or auger conveyor, are used as an efficient way to move a wide variety of materials. The auger is used to move material along a path using a helical screw. The process of drilling with a helical bit involves aspects of both: the creation of the hole with the tip of the bit is drilling, while moving the waste material out of the hole along the helical path is augering. Not all drilling involves augering (oil field drilling uses a pump to move the material). Screw conveyors in oilfield are often used horizontally or at a slight incline as an efficient way to move drilling fluids with drill cuttings.

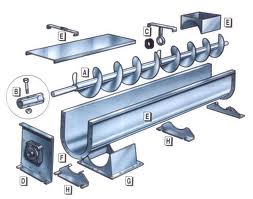

Main components of Auger screw:

Motor, control panel, Screw( including blade and shaft),Conveyor housing, Supporting feet and saddles, Feed and discharge spouts, Cover, Through end, etc.

Screw consists of a several of blades of helix shape welded to a pipe or shaft. It moves the material. The following specs should be calculated carefully for proper use: Flight outside diameter, type of blades, spacing between the blades, thickness of the external diameter and interior shaft and rotation direction.

N has standard oilfield used 12” or 14” three section auger Screw, with drive, middle and end section, with inlet and outlet on top of the cover. It adopts explosion proof electric motor and control panel, suitable for container shipment.