GN is a well-known brand from China, its full company name is HeiBei GN Solids Control Co.,Ltd which locadted in No.3 Industry Road, Dachang Chaobai River Development Area,Langfang, China; We are known around the world for unique innovation without compromise, sophistication while maintaining user simplicity, and superb service to our extremely wide customer base.specializing in supplying solids control& waste management equipment to the global market.

A solid control system typically refers to a system that manages and controls the drilling fluids or mud during oil and gas drilling operations. It plays a crucial role in maintaining the stability and efficiency of the drilling process by controlling parameters such as viscosity, density, and chemical composition of the drilling fluid. This helps in preventing wellbore instability, managing formation pressures, and ensuring smooth drilling operations.

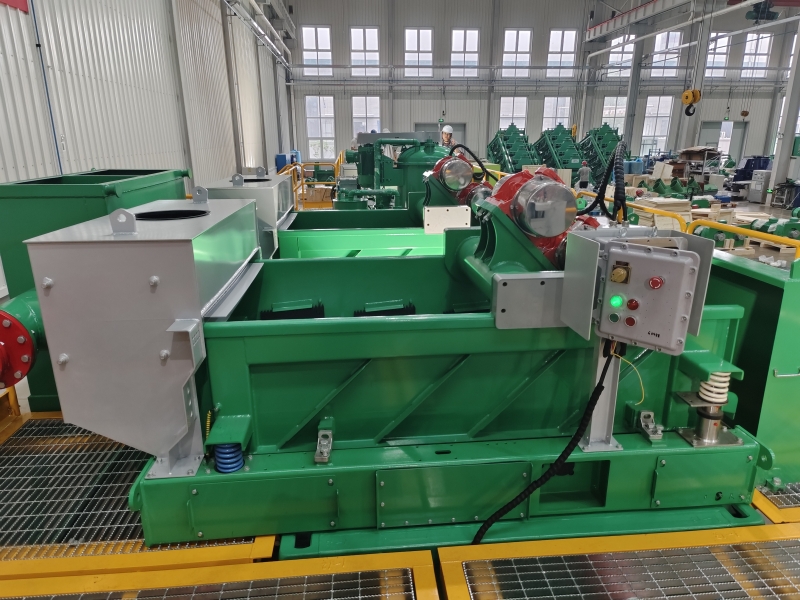

A shale shaker is a vital component of a solid control system used in oil and gas drilling operations. Its primary function is to separate drilling cuttings from the drilling fluid (mud). Here’s how it typically works:

- Screening: The shale shaker uses a series of screens with different mesh sizes to separate larger solids (drilling cuttings) from the drilling fluid. The fluid passes through the screens while the solids are retained.

- Vibration: The shale shaker vibrates rapidly to enhance the separation process. This vibration helps to convey the solids along the screen and encourages fluid to pass through.

- Efficiency: By removing solids from the drilling fluid early in the process, the shale shaker helps maintain the properties of the mud, such as viscosity and density, which are crucial for efficient drilling and protecting the wellbore.

A vacuum degasser is another critical component in the solid control system used in drilling operations, particularly in oil and gas exploration. Its primary function is to remove entrained gas, primarily methane, from the drilling fluid (mud). Here’s how it works and why it’s important:

- Purpose: During drilling, gases such as methane can enter the drilling fluid from the formation being drilled. These gases reduce the density and increase the compressibility of the mud, which can lead to several issues such as wellbore instability, formation damage, and reduced drilling efficiency.

- Operation: The vacuum degasser operates by creating a low-pressure environment inside a vessel or chamber. As the mud is pumped into this chamber, the reduced pressure allows the gases dissolved in the mud to come out of solution and form bubbles. These bubbles are then vented out of the degasser, leaving the mud effectively degassed.

A mud hopper is an essential component in the solid control system used during drilling operations, particularly in oil and gas exploration. Its primary function is to mix drilling additives, such as chemicals, clays, or polymers, into the drilling fluid (mud) to achieve desired properties and maintain optimal performance. Here’s how it typically works and its importance:

- Function: The mud hopper is designed to rapidly and efficiently mix dry or liquid additives into the drilling fluid. These additives are crucial for controlling viscosity, density, pH levels, and other properties of the mud to suit various drilling conditions and challenges.

- Operation: Mud hoppers are equipped with nozzles or jets that inject the additives into the mud stream. Dry additives are usually added through a hopper that feeds into the mud flow, while liquid additives can be injected directly through pumps or nozzles.

- Mixing: As the additives are introduced into the mud, they are mixed thoroughly to ensure uniform distribution. This mixing process is crucial to achieve consistent mud properties throughout the drilling operation.

For our latest equipment brochure or more info, please visit our unique official website: www.gnsolidscontrol.com

MichaelSong

Sales Engineer Manager

Whatsapp:+86 17801799913