As a part of rig package, mud system is a separate but an essential part, the handling of drilling fluids can save huge cost of drilling. In the early oil industry open earthen pits were used as settling area to separate solids and mud thereby acting as a solids control equipment.

Now, with the stringent environmental regulations and high mud costs, the economics of an effective mud system come into consideration. Different solids control companies introduce zero-discharge systems, closed-loop systems, “quick move” technology, screening technology, disposal options etc. No reserve-mud pit is used in a truly closed mud system. Mud is continually processed primarily by mechanical means, such as screening, hydrocyclone and centrifuging to remove solids initially. A second stage to remove colloidal solids is by wastewater cleanup techniques.

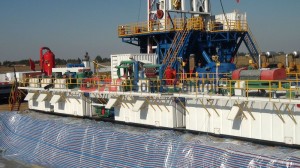

Major components of a mud system, including:

Mud gas separator, flare ignition device

Shale shaker, mud cleaner(or desander, desilter), vacuum degasser, decanter centrifuge , centrifugal pump, mud hopper, mud agitator, mud gun, mud tank and others, such as cutting dryer, screw auger, mud cooling unit,etc.

In most times, a mud system do not only have one mud tank, trip tank, water tank, diesel tank, storage tank, pill tank, mixing tank, suction tank are also included. All these tanks with equipments compose of the mud system. The rig package is composed of mud system, mud pump, draw-works, Kelly hose, Goose-neck, Traveling block, Drill line, Crown block, Monkey board, drill pipe, Pipe rack (floor),Swivel ,Kelly drive, Rotary table, Drill floor, Bell nipple, Blowout preventer ,Drill string, Drill bit, Wellhead, Flow line, etc.