The desander and desilter are important parts of solids control system, and the hydrocyclone cones is the key component. Here is the detailed introduction of the cones design, the use and ability of desander desilter cones, and then I introduce you the manufacturers of desander cone and desilter cones.

Desander desilter cones design

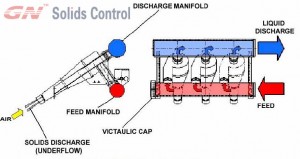

The desander cone and desilter cones all are also referred as hydrocyclone cones, cones are basically separate the solids from drilling fluids. The separation process is carried out by employing centrifugal forces. The Cones are made of high durameter polyurethane with optional steel inserts, which ensure consistent productivity.

Use and ability of desander desilter cones

Desander Cones remove abrasive, coarse solid particles upto 60 microns.

Desander Cones are available in 10″ attachments with a 4″ inlet and 6″ outlet.

Desilter Cones remove fine sand and silt down to 20 microns.

Desilter Cones are available of 4″ size that have a 2″ inlet and a 2″ outlet.

Desander cone and desilter cone manufacturer

GN Solids Control is a professional manufacturer of solids control equipment, GN supply all the parts of solids control system, including cones of desander and desilter.

Mud cleaner desilter cones to Indonesia

We just finish production of 16 desilter cones,and the desilter cones are ready for delivery to Indonesia.

The desilter of mud cleaner,and desilter usually uses 4″ hydrocyclone cones.

As a manufacturer of mud cleaner,and desilter,GN provide fast and reliable spare parts for our equipments.

To learn more about Hydrocyclone Separator