Slurry treatment system is very important for slurry tunnel boring. GN Solids Control is also very professional at TBM (Tunnel Boring Machine) slurry treatment system. The picture beside is the most popular slurry treatment system. It usually contains a linear motion shale shaker (GNZS63-3, or GNZS83-3), and a mud cleaner, hydro-cyclones with linear motion shale shaker (GNZS63-3, or GNZS83-3). Also mud tank for storage, centrifugal pump to transport.

Machine) slurry treatment system. The picture beside is the most popular slurry treatment system. It usually contains a linear motion shale shaker (GNZS63-3, or GNZS83-3), and a mud cleaner, hydro-cyclones with linear motion shale shaker (GNZS63-3, or GNZS83-3). Also mud tank for storage, centrifugal pump to transport.

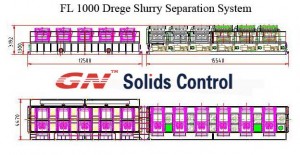

Operation of Dredge Slurry Separation System

After dredging work, we should separate the slurry, for envioment friendly or other purpose. GN FL 1000 is one perfect system for about 3000 gpm capacity. We will take this for example to introduce How the slurry separation work.

How the Slurry Separation Work

1. Entry: the dredged slurry enters the shale shaker directly from the dredge. In GN FL 1000, the slurry enters into the GNZS 83-3 shale shaker, (5 pcs)

2. Shale Shaker: there are 5 GNZS 83-3 shale shakers in FL 1000, treating capacity is 3000 gpm. With the proper shaker screen, the debris like grass, roots, leaves, cans, plastic, rags, and bottles can be separated, then the slurry to the next stage is in conditon that the biggest particles is 47-76um.

3. Desanding tank: The slurry going through the shale shaker, and drop into a tank, where it is picked up by a centrifugal pump.

4. De-sanding and De-silting: the pump, means SB 8*6*14 centrifugal pump moves the slurry to the second phase. Then it passs the desanding hydro-cyclones, to the desilting tank. Then the slurry will be pumped again to the desilting hydrocyclones. Dropped into another process tank. Until now the debris bigger than 20um (15-47um) are separated. Equipments referred is ZQJ 250 desander, and ZQJ 100 desilter. Continue reading “Operation of Dredge Slurry Separation System”

Drilling Fluid System

Mud rotary drilling is popular in wellbore drilling, offshore works, well drilling, Horizontal directly drilling, mining, geotechnical. Drilling fluid system is one very important part of the drilling work. The two main parts of the drilling fluid system is the actual drilling fluid and the solids control equipments, to separate the cuttings from the drilling mud at the surface, and circulating water based drilling fluid.

As we all know the quality and charactor of the drilling fluid effects the drilling works. The viscosity, density, fluid loss control, sand content, gel strength, and so on. The drilling fluid system is used to control them.

If not use the drilling fluid system correctly, effiently, there must be some trouble. High fluid density causes pressure in the formation of the borehole. This pressure drives the drilling fluid through the filter cake into the formation, leads to excessive drilling fluid loss to the formation, and extends well development time required to remove the mud from the formation. As the fluid density increases, the pressure required to move the fluid up the borehole also increases, leading to high mud pump pressure requirements. Continue reading “Drilling Fluid System”

Drilling Fluid Desilting

Desilting and desilting kown as part of drilling mud cleaning is one important part of solids control system. While in solids control system, the desanding and desilting equipments are called desander and desilter, or combine them, as mud cleaner.

In a solids control system, desilting is after desanding work, and depends on the drilling mud character, the desanding or desilting unit is not always need. GN Solids Control always can give our clients a appropriate solution.

Desilting cones is the main and core part of the desilter. The dimension of the hydrocyclones is 4″. ZQJ 100s and ZQJ 100 is the usual model of GN, ZQJ100s means the desilting equipments with a small shale shaker.

Drilling Fluids Desilting equipments (desilter) Manufacturers

GN soldis control is one of the most important solids control equipment manufacturer.

Derrick, NOV Brandt, Mi swaco are very famous US manufacturers on solids control equipments.

Desilter of GN soldis control is popular all over the world

Drilling fluids desilting equipments (desilter) manufactured by GN solids control is very popular all over the world.

Five Sets of Desanders and Desilters for Kuwait Clients

Offshore Mud Mixing Equipment

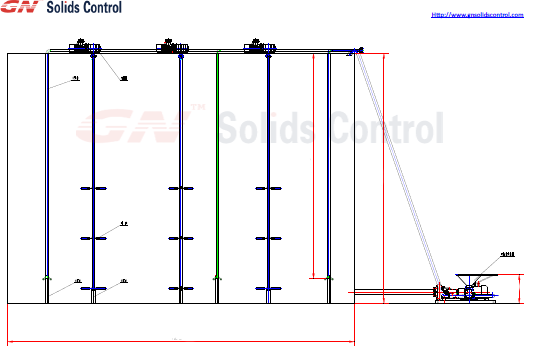

Mud mixing equipment ususlly includes mud hopper, mud gun, mud agitator, jet mud mixer. Offshore mud mixing equipments needs marine explorsion proof motors for mud agitator and centrifugal pump.

Tanks of offshore drilling is usually different, so mud mixing unit is very special, the shaft of mud agitator must adopt the depth of the tank, so does the length of the mud gun.

One sample solution for our customer:

Usually our agitator have two impellers, as the tank is very deep, we design three for them now.

Continue reading “Offshore Mud Mixing Equipment”

Continue reading “Offshore Mud Mixing Equipment”

NOV Mud Conditioner and GN Mud Cleaner

There are a lot of names given to the combination of hydrocyclone and shale shaker. In NOV, it is called mud conditioner; while Derrick, flow line cleaner; Mi swaco, mud cleaner; in China, GN Solids Control, also named it mud cleaner.

There are six mud conditioner types: King Cobra Mud Conditioner; Cobra Mud Conditioner; LCM-3D Mud Conditioner; Mini Cobra 2-Panel Mud Conditioner; Mini Cobra 3-Panel Mud Conditioner; King Cobra Venom Mud Conditioner. The differences is the shale shaker, and the number of cones.

There are 5 models in GN Solids Control: GNZJ83-3 GNPJ70-3 GNZJ63-3 GNZJ83-2 GNTJ60, two kinds of shaker GNZS Linear Motion Shale Shaker, GNPS Balanced elliptical shale shaker are available.

The National Oilwell Varco? Brandt? King Cobra Mud Conditioner utilizes a combination of hydrocyclones and a King Cobra shale shaker to separate solids from liquid. The combination of hydrocyclone cones utilized is dependent upon the specific application of duty. Cone combinations typically consist of a desander cones (10-inch or 12-inch) and desilter cones (4-inch) which are properly sized to handle over 125% of the flow rate.

Continue reading “NOV Mud Conditioner and GN Mud Cleaner”

How to Clean the Shaker Screens

After operating the solids control system with the working of the drilling, to save cost, lengthen the life of shaker screen is very important, the essential thing is an active screen maintance program.

Screen panel flexing caused by dirty, missing or worn deck rubbers. Clean dirty deck rubbers or replace missing or worn deck rubbers. Always change all deck rubbers in the affected section of the shaker.

OLD WAY TO CLEAN SHAKER SCREEN

Remove any solids that become adhered to the screen cloth. Use a water hose or pressure washer to clean screens.  NEVER clean screens with a wire brush. If screens become blinded with near size particles it is best to remove and wash with a pressure washer from the back side. Always clean screens if the shaker will be idle for a long period of time. Mud and cuttings that are allowed to dry on screens will eventually lead to premature failure. Continue reading “How to Clean the Shaker Screens”

NEVER clean screens with a wire brush. If screens become blinded with near size particles it is best to remove and wash with a pressure washer from the back side. Always clean screens if the shaker will be idle for a long period of time. Mud and cuttings that are allowed to dry on screens will eventually lead to premature failure. Continue reading “How to Clean the Shaker Screens”

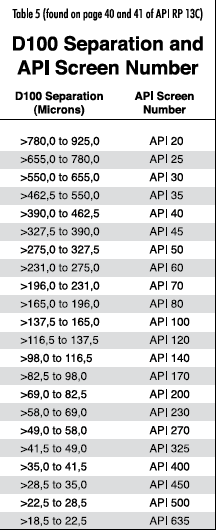

API Shaker Screen Numbers

API RP 13C is the latest labeling procedure for shaker screens. Internationally, API RP 13C is ISO 13501.Now the API Screen Numbers are determined by the D100 separation (Microns).

Introduction of API RP 13C

The new procedure API RP 13C is a revision of the previous API RP 13E, which was based on optical measurements of the screen opening using a microscope and computer analysis. Under API RP 13E, screen designations were based on individual manufacturer test methods which produced inconsistent labeling. So it has many different criterion, and when we choose the shaker screen for the shakers, we are easy to get in trouble, even now with the API RP13C, we must convert the old one to the new label, then we can choose the right screen.

How They Test

The API RP 13C test contain two parts: cut point and conductance. It is a current criterion. Used all over the world.The tests describe a screen without predicting its performance.

The cut point test is based on a time-proven testing method used by ASTM to classify particles by size.

The D100 separation is used for assigning screen designations. D100 means that

100 percent of the particles larger than the test screen will be retained, and all finer particles will pass through.

How to Find the Right Replacement Shaker Screens Continue reading “API Shaker Screen Numbers”

Drilling Mud Flow Line Divider

Flow line divider is also one important part of drilling mud system. And it can be used with solids control system o f GN Solids Control. However, it used not very popular in China.

Main Introduction of Flow Line Divider

Drilling mud flow line divider is used to optimize the solids removal capabilities of shale shakers. In this article, we introduce famous brand flow line divider like Derrick Flo-Divider, and Brandt Dual Cartridge Scalper, Baroid’s Unique SupaVac™ SV400 Cuttings Collection and Pumping System.

By pooling and dividing the drill fluid upstream from the shale shakers, the Flo-Divider ensures that each shaker receives an equal flow of drilling mud and an equal distribution of drilled solids.

Brand flow line divider

Derrick Flo Divider have 4 types of model by the divided way: 3-way, 4-way, 5-way, and 6-way, it fits easily onto most rigs, and is applicable for all derrick shakers.

Brandt flo line divider: The Brandt product line of NU-TEC Gumbo Removal Equipment is the first step in effective solids removal when sticky clays and gumbo are drilled. The Gumbo Box™, in conjunction with either the Gumbo Chain™ or Scalper™, can virtually eliminate plugged flow-lines by removing the gumbo before it reaches the shale shakers.

The SupaVac™ SV400 unit is a compact, air-operated, vacuum recovery and pressure discharge pump. This system is designed to operate in hazardous locations, safely collecting and pumping materials such as drill cuttings, tank bottoms, heavy crude sludge and sand slurries.

Continue reading “Drilling Mud Flow Line Divider”

Slurry Pump for HDD Mud System

Rugged, Efficient, Simple, withe long life, we think it is the best product we have ever used. A customer send email to us and highly recommend the slurry pump. Slurry pump is usually used to supply drilling fluids to decanter centrifuge.

However,Slurry pump is one important part for HDD Mud System, single tank mud system to multi-tanks system. Anyway  shale shaker is the essential part, and the slurry pump which supply slurry to the shale shaker is indispensable.

shale shaker is the essential part, and the slurry pump which supply slurry to the shale shaker is indispensable.

GN Solids Control is very professional at solids control for HDD mud system. We can supply all kinds of customized HDD equipments just as you required. The slurry pump is used to pump the slurry to the solids control system.

To sum up, the YZ submersible slurry pump is the ideal centrifugal pump for Feeding Shale Shaker from Mud Pit for HDD Mud Recycling.

The YZ submersible slurry pump and the HDD mud recycling system made by GN Solids Control is widely used all over the world. Many HDD companies use YZS slurry pump with solids control system from GN company with Vemeer HDD drilling rigs.

Some good news from GN Solids Control about the HDD mud recycling system with YZ slurry pump. Continue reading “Slurry Pump for HDD Mud System”