GN Solids Control Co., Ltd. is a Chinese company specializing in the design, manufacturing, and service of solid control systems and related equipment for the oil and gas drilling industry.

Oil sludge is a hazardous byproduct of drilling, tank cleaning, and refinery operations, containing oil, water, and solid particles. GN Solids Control provides advanced oil sludge treatment systems to recover oil, reduce waste, and meet environmental regulations.

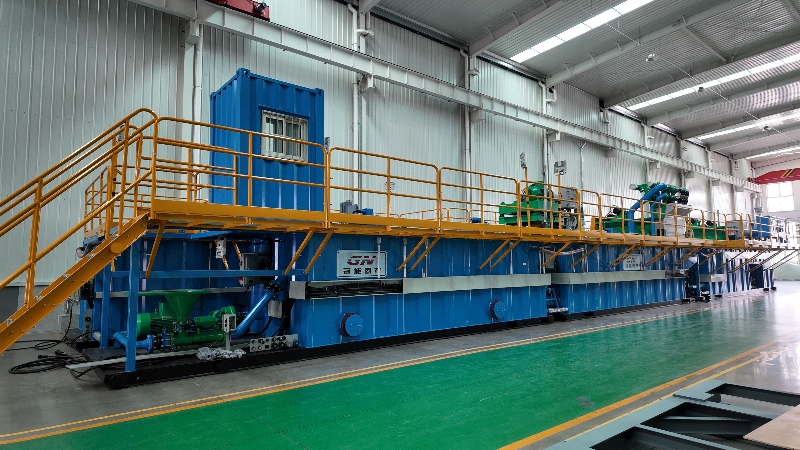

GN Oil Sludge Treatment Process GN’s system typically includes mechanical separation, thermal treatment, and chemical conditioning for maximum oil recovery.

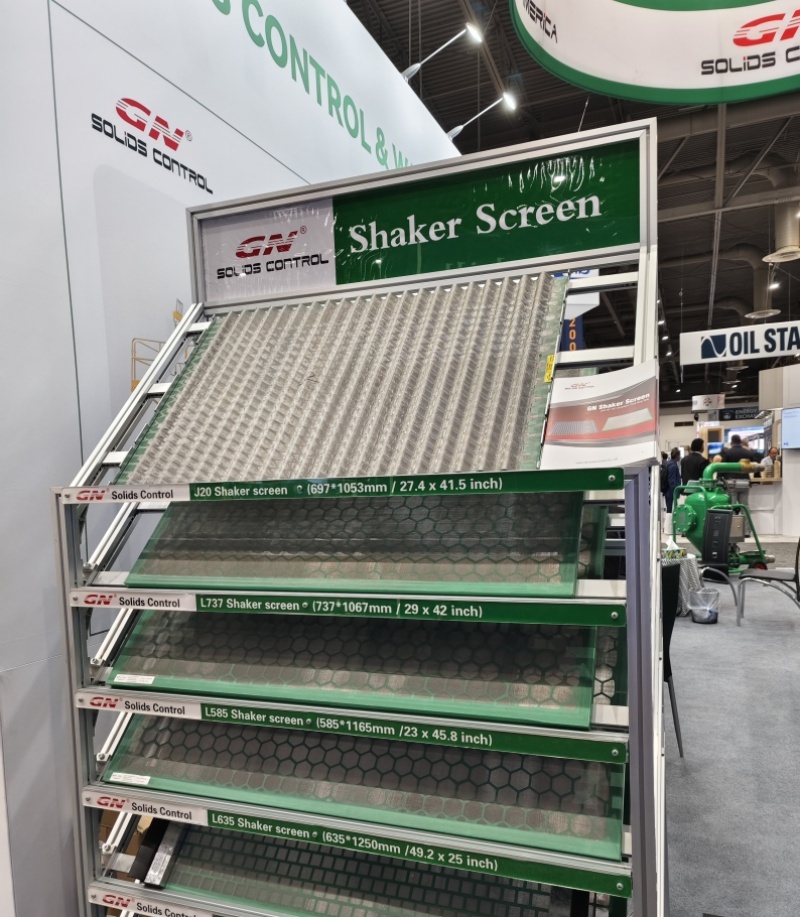

- Pretreatment (Sludge Screening & Heating) Screw Pump/Grit Separator → Removes large debris.

Heating System (optional) → Lowers viscosity for better separation.

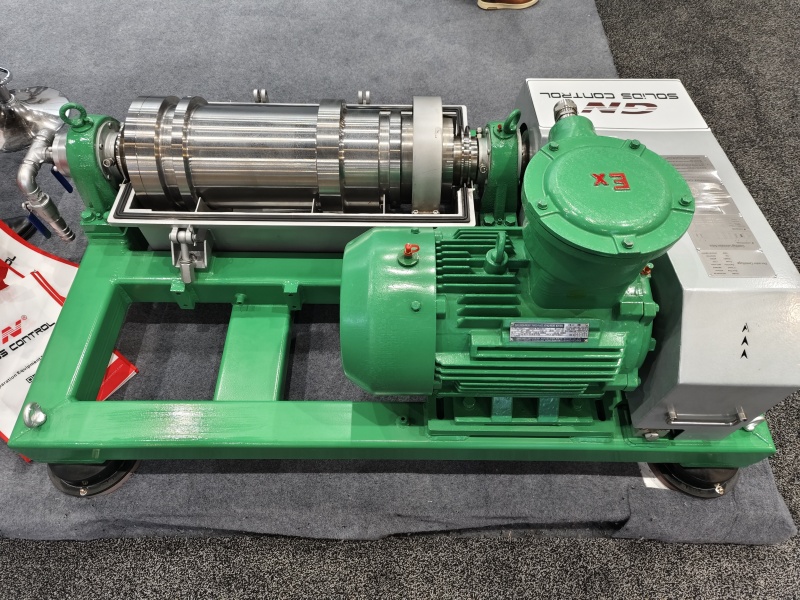

- Primary Separation (3-Phase Decanter Centrifuge) GNLW Series Centrifuge separates:

Recovered Oil (reusable)

Water (can be treated further)

Solids (≤5% residual oil, safe for disposal)

- Secondary Treatment (Thermal Desorption or Chemical Washing) Thermal Desorption Unit (TDU) → For heavy sludge, removes oil via heating (optional).

Chemical Demulsifiers → Enhances oil-water separation.

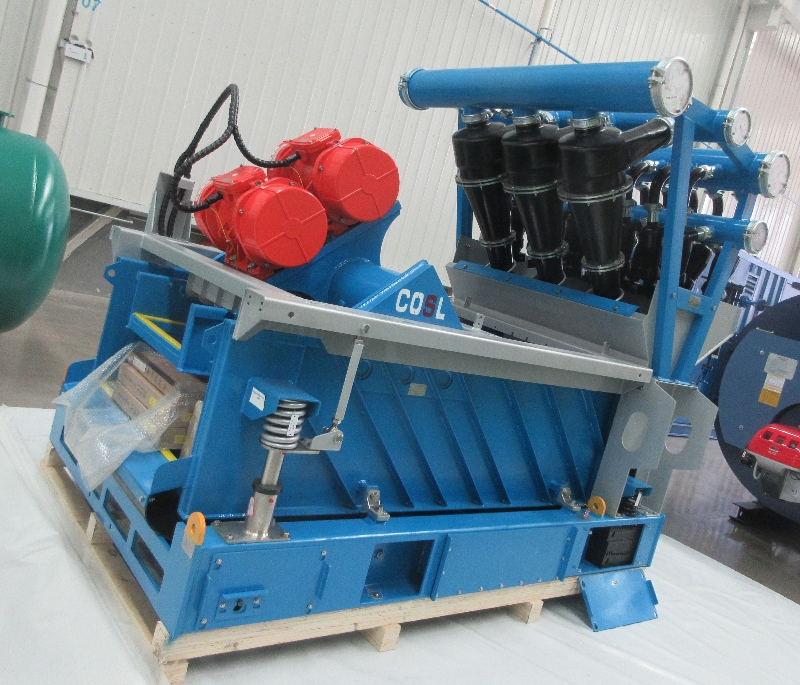

Key Equipment in GN’s Oil Sludge Treatment System

Equipment Function

Sludge Transfer Pump Moves sludge into the system

Heating Mixer Reduces viscosity

3-Phase Centrifuge Separates oil, water, solids

Thermal Desorption Unit Deep cleaning for solids

Screw Conveyor Discharges dried solids

Oil/Water Storage Tanks Collects recovered fluids

Applications

Oilfield Drilling Waste (OBM cuttings, pit cleaning)

Tank Bottom Sludge Treatment

Refinery Waste Processing

Oil Spill Cleanup (soil remediation)

Why Choose GN Solids Control?

10+ Years of Experience in sludge treatment.

Customizable Solutions (small mobile units to large plants).

Global Support (Africa, Middle East, Americas, Asia).

Would you like technical specifications or a case study?

Find MichaelSong contact below.

Whatsapp: + 86 178 0179 9913

Email: michael@gnsolidscontrol.com/michael@gnsolidscontrol.co