GN Solids Control drill cutting dryer is widely used in oil-based mud drilling sites around the world. Recently, our after-sales engineers conducted customer return visits to several sets of drill chip dryers sold to Xinjiang. Received good reviews from customers.

The drill cuttings dryer is designed to further process the cuttings discharged from the shale shaker of the solid control system to recover more drilling mud and reduce waste emissions. Greatly reduce waste disposal costs and save consumption of drilling fluid base fluid. GN Solids Control vertical cuttings dryer can reduce the oil content of cuttings(OOC) to less than 5%.

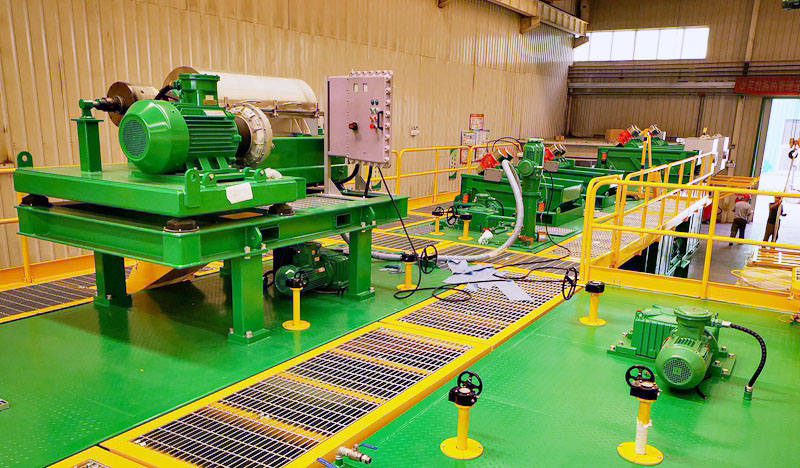

GN Solids Control can provide screw conveyors for receiving and feeding, or drill cutting conveying pumps. Drilling cutting dryer, decanter centrifuge, slurry feed screw pump, installation tank and bracket, discharge screw conveyor and corresponding quick-mount bracket. Meet the requirements of customers’ overall solutions.

1: Screw Conveyor——According to the layout of the on-site mud recovery system, GN Solids Control provides lifting support legs for screw conveyor installation, which are used to collect drilling debris from the mud system, especially the first-level shale shaker, and transport it to the rock cuttings. Dry machine. If more flexible equipment layout is needed on site, GN Solids Control recommends replacing the screw conveyor with a sludge vacuum pump.

2: Rock cuttings dryer-Rock cuttings dryer is the key equipment of the system. It is used to shake off the oil and liquid in the cuttings by centrifugal force, thereby reducing the oil content of the cuttings by less than 5%. GN Solids Control’s cuttings dryer is equipped with an air knife and flushing system to ensure that the dryer runs for a long time without blocking the screen basket. Speeds of up to 900 rpm ensure the dryness of the cuttings discharged from the cuttings dryer.

3: High-speed Decanter centrifuge—The liquid discharged from the drill cuttings dryer is pumped to the Decanter centrifuge for processing, removing ultra-fine solids, so that the drilling fluid can continue to be used for drilling.

In addition to the integrated drilling drying system, GN Solids Control can also provide a modular design, that is, each equipment is equipped with a corresponding installation tank or bracket, which is convenient for customers to make different combinations or use equipment individually according to the working conditions.

For more information on GN Solids Control, please feel free to contact us.