GN Solids Control is a mud treatment equipment supplier. After more than ten years of continuous development, GN Solids Control mud treatment equipment has been successfully sold to many countries and regions around the world. Recently, GN Solids Control delivered a batch of HDD mud treatment equipment to a Chinese engineering company.

GN Solids Control’s HDD mud treatment system is divided into two large series, namely economic mud treatment system and high-profile mud treatment system. The main difference is that the economical mud treatment system is mainly used for the purification and recycling of mud, but it does not have a mud tank for storing mud and a jet mud mixing device for adding materials. It needs to be equipped with an external slurry storage device and a jet mixing device separately. . The high-profile mud treatment system integrates the functions of mud recovery, mud storage and mud mixing, and can achieve multi-stage mud purification treatment, which can meet the needs of high-end and medium-sized drilling rigs.

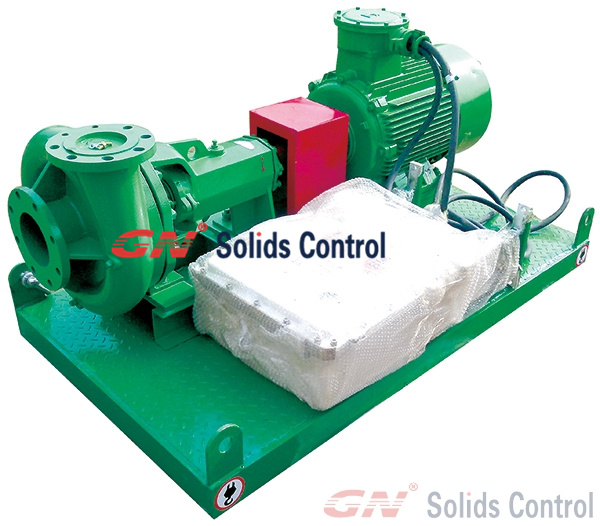

The working principle of the GN Solids Control Trenchless Mud Purifier is that the mud in the mud pool is first sucked into the shale shaker logging tank through the submerged slurry pump, and then into the shale shaker for the bottom coarse screen to remove the mud in the mud. The solid phase of the large particles is separated, and then the liquid phase enters the slurry storage tank, and then the mud is pumped out of the slurry storage tank by the sand pump and transported to the desander. The desander cyclone screens out the fine particles in the mud. The solid phase falls into the upper layer of the vibrating screen to be sieved again, and the liquid phase enters the slurry storage tank. The re-sieved solid phase is relatively dry and can be discharged for treatment, and the liquid slurry continues to be recycled.

In addition to the standard configuration, the GN Solids Control non-excavation mud treatment system can also be designed into a skid-mounted, hydraulic lift, and vehicle-mounted type according to the customer’s project request to meet the requirements of customers for rapid transportation in different working conditions.

If you have any needs and questions regarding trenchless mud treatment, you can contact us at any time.