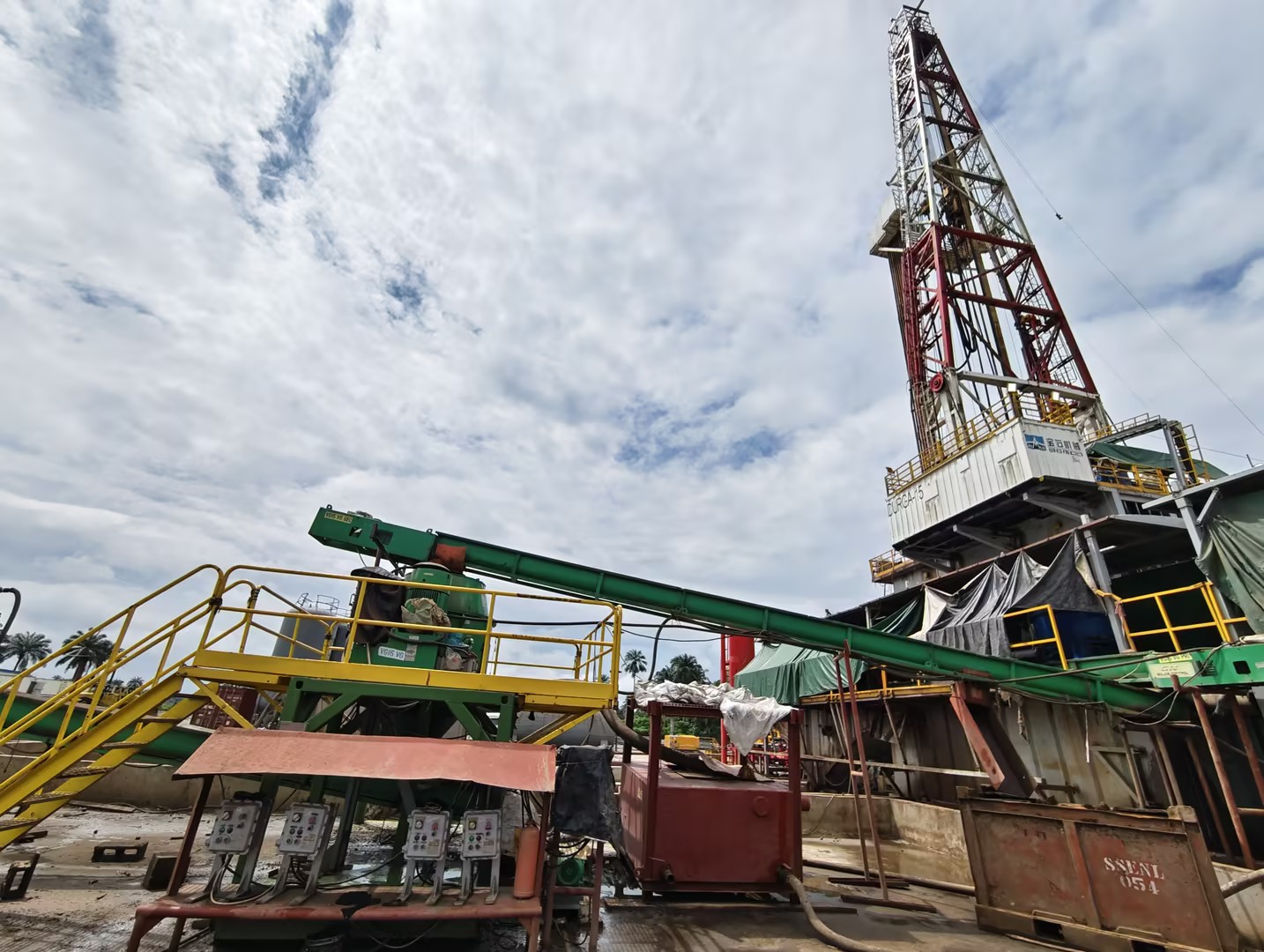

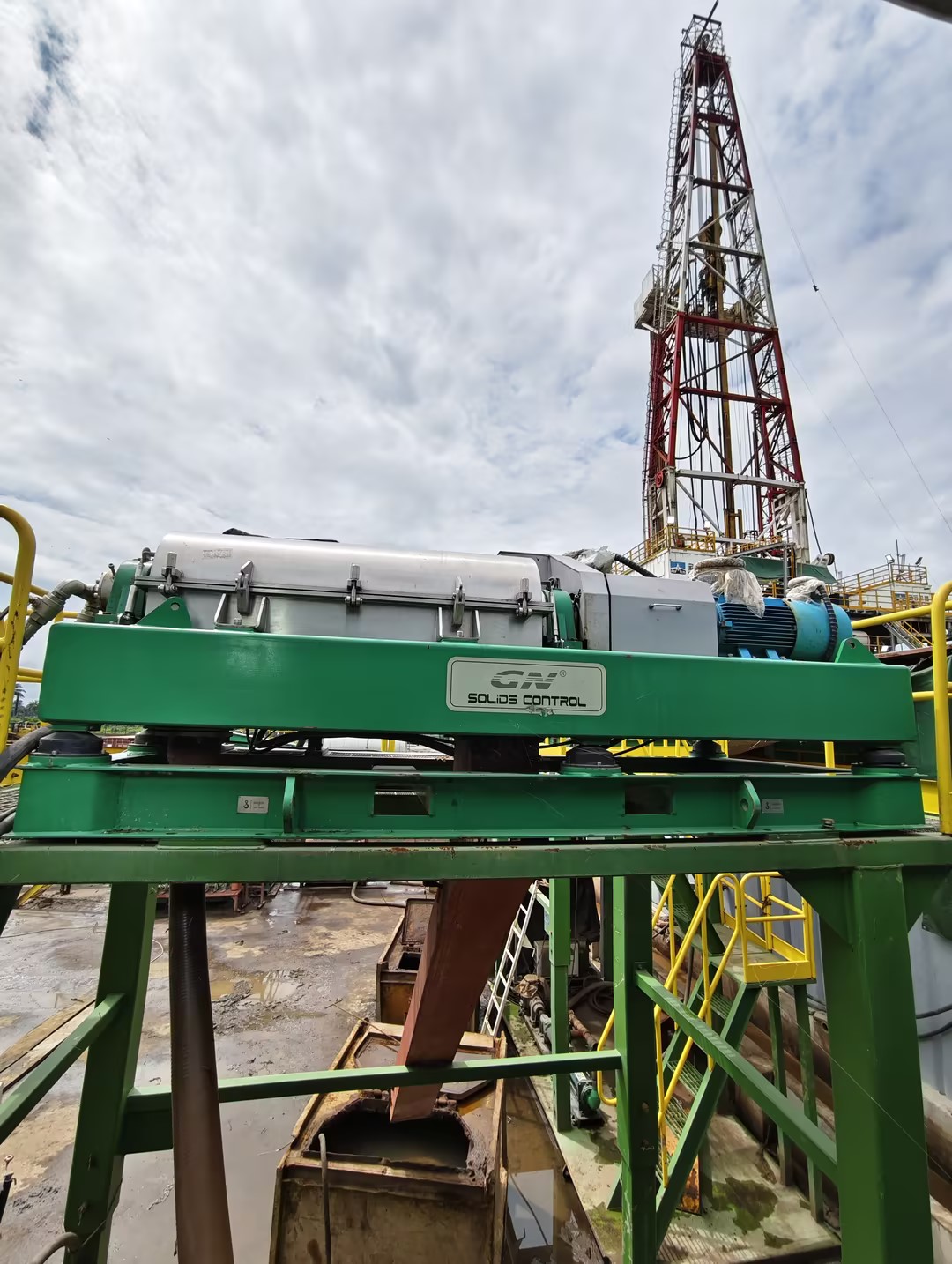

Hebei GN Solids Control Co., Ltd. has specialized in solids control and waste management equipment since 2008. GN stands as one of the largest manufacturers of solids control equipment globally. We operate three factories spanning a total area of 110,000 square meters in China and maintain branch offices with service capabilities in both the United States and Australia. Designated as a National High-Tech Enterprise, GN boasts a robust management system. Since 2010, we have consecutively held the American API Quality Management System Certification for 15 years and maintained China Classification Society certifications for ISO9001, ISO14001, and ISO45001 over many years. Our solids control equipment bears certifications from EU CE, ATEX, and International IECEx. GN employs an ERP Cloud + CRM Cloud management system for seamless production and operation, ensuring digital control over the production process and quality traceability. Approximately 70% of our products are exported internationally, reaching over 70 countries worldwide.

GN Product Lines

- Solids Control Equipment:Shale Shaker, Mud Cleaner ,Desander ,Desilter, Decanter Centrifuge, Centrifugal Pumps, Agitator, Degassers, Mixing Hoppers, Mud Tanks etc.

- Waste Management Equipment: Oil Sludge Treatment Equipment, Vertical Cutting Dryer,HI-G Drying Shaker,Decanter Centrifuge,Slurry Vacuum Pump, Dewatering Unit,Screw Pumps, Screw Conveyor etc.

- Industry Decanter Centrifuge: Available in 9/14/18/22/30 inch bowl, with VFD or FHD drive system.

- Shale Shaker Screen: API RP 13C compliant shaker screen for all main shale shaker brand.

- Mud System: Oil Gas Mud Circulation System, HDD Mud Recycling System, TBM Slurry Separation Plant, Oil Sludge Treatment System and Mud System for Core Drilling/Waterwell/ Geothermal well/CBM

GN Solids Control Advantages?

1.Rich Experience

Since 2008, GN has accumulated over 17 years of expertise in researching, developing, and manufacturing solids control equipment. GN is recognized as both a National High-Tech Enterprise and a nationally renowned specialized, innovative small giant enterprise.

2.Robust Manufacturing Capabilities

Occupying a total area of 110,000 square meters, GN Solids Control boasts three primary manufacturing facilities equipped with cutting-edge machinery, including Automatic Welding Robot Workstations, Large Laser Cutting Machines, Advanced CNC Machining Centers, and Large Automatic Injection Molding Machines for shaker screens.

3.Well-established Management System

GN has earned certifications for ISO 9001, ISO 14001, ISO 45001, as well as the American API Q1 Quality Management System. Additionally, GN’s products have secured EU CE and ATEX certifications. GN utilizes an ERP Cloud+CRM Cloud management system.

4.Extensive Market Share

Our products are exported to more than 70 countries and regions globally, gaining wide recognition from both domestic and international customers. Furthermore, we have established branches in Houston, USA, and Brisbane, Australia

For more case info,Find Michael.

Whatsapp: + 86 178 0179 9913

Email: michael@gnseparation.com