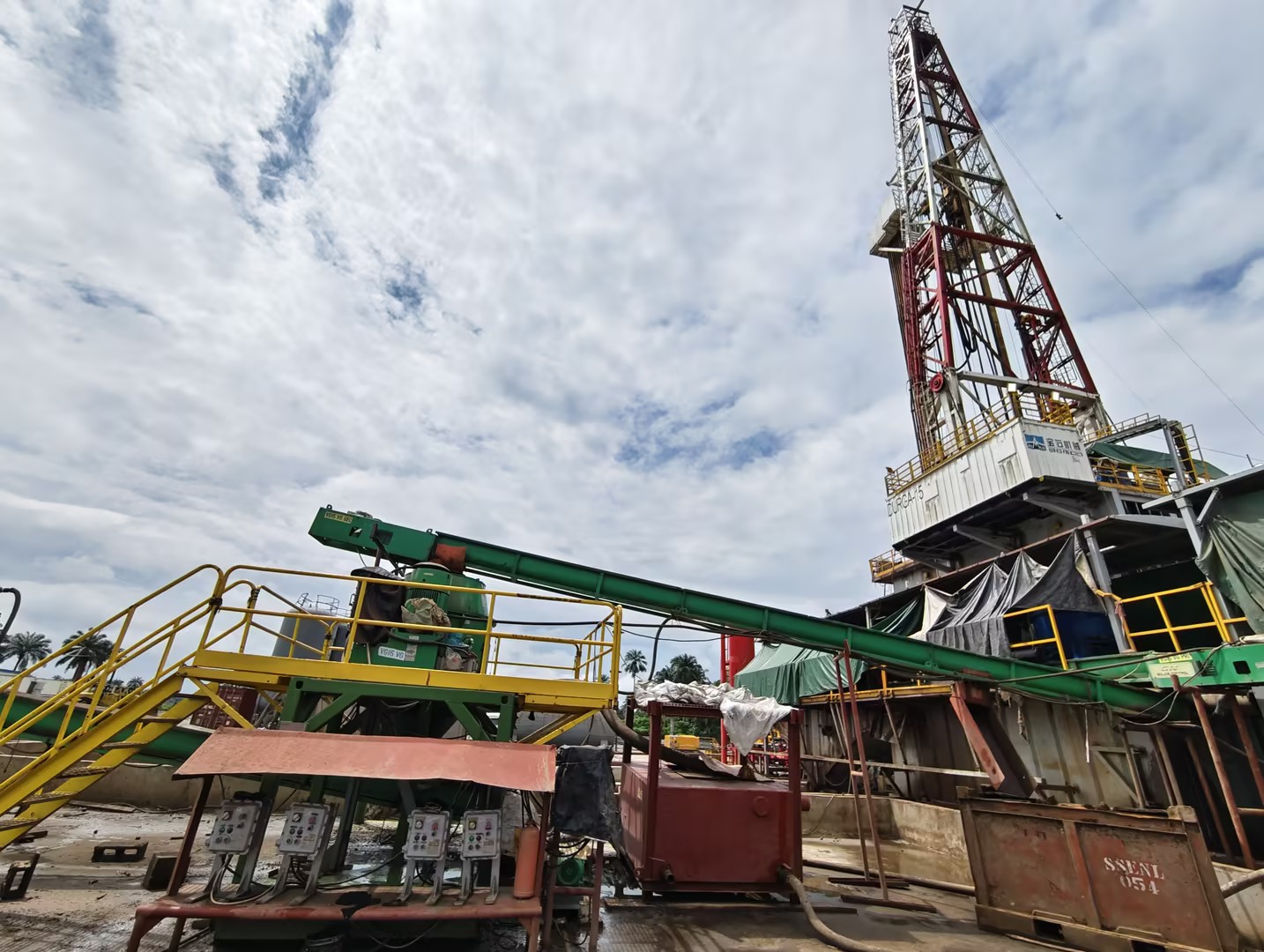

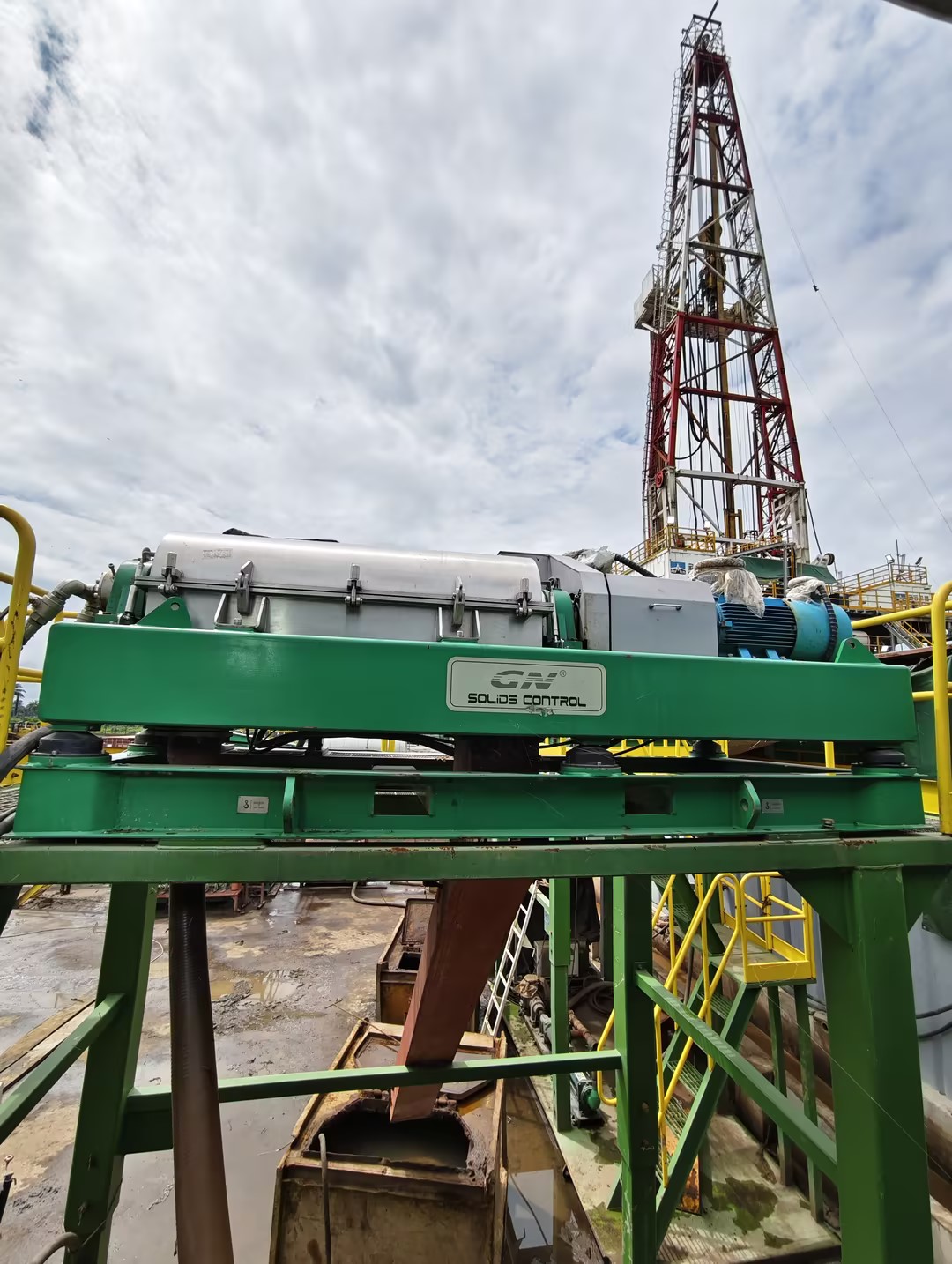

Hebei GN Solids Control Co., Ltd. has specialized in solids control and waste management equipment since 2008. GN stands as one of the largest manufacturers of solids control equipment globally. We operate three factories spanning a total area of 110,000 square meters in China and maintain branch offices with service capabilities in both the United States and Australia. Designated as a National High-Tech Enterprise, GN boasts a robust management system. Since 2010, we have consecutively held the American API Quality Management System Certification for 15 years and maintained China Classification Society certifications for ISO9001, ISO14001, and ISO45001 over many years. Our solids control equipment bears certifications from EU CE, ATEX, and International IECEx. GN employs an ERP Cloud + CRM Cloud management system for seamless production and operation, ensuring digital control over the production process and quality traceability. Approximately 70% of our products are exported internationally, reaching over 70 countries worldwide.

GN Product Lines

- Solids Control Equipment:Shale Shaker, Mud Cleaner ,Desander ,Desilter, Decanter Centrifuge, Centrifugal Pumps, Agitator, Degassers, Mixing Hoppers, Mud Tanks etc.

- Waste Management Equipment: Oil Sludge Treatment Equipment, Vertical Cutting Dryer,HI-G Drying Shaker,Decanter Centrifuge,Slurry Vacuum Pump, Dewatering Unit,Screw Pumps, Screw Conveyor etc.

- Industry Decanter Centrifuge: Available in 9/14/18/22/30 inch bowl, with VFD or FHD drive system.

- Shale Shaker Screen: API RP 13C compliant shaker screen for all main shale shaker brand.

- Mud System: Oil Gas Mud Circulation System, HDD Mud Recycling System, TBM Slurry Separation Plant, Oil Sludge Treatment System and Mud System for Core Drilling/Waterwell/ Geothermal well/CBM.

Hydraulic drive mini centrifuges are purpose-built to treat drilling fluid at remote diamond core drilling sites. They use a diesel engine to power a hydraulic motor, eliminating the need for grid electricity, and are designed for portability in rugged terrain.

Here is a comparison of two available models:

Feature GN Solids Control Hydraulic Centrifuge Multi-Power Products Portable Centrifuge System (PCS)

Primary Power Source Diesel-powered hydraulic motor Diesel/hydraulic system

Key Design Principle Modular & lightweight for helicopter transport Compact, modular, man- & heli-portable

Centrifuge Bowl Size 9-inch bowl 9-inch x 35-inch bowl

Separation Performance Removes 2-5 micron solids at 3800 RPM (1777 G-force) 3-5 micron separation at 3900 RPM

Processing Capacity Not specified in detail Up to 150 LPM (40 GPM)

System Weight Not specified, but designed for helicopter lifting Total system: ~1,075 kg

Core Benefit Mud management, waste reduction, environmental compliance Closed-loop recycling, reduces water use by up to 90%

⚙️ How It Works and Key Benefits

These units are critical for maintaining drilling efficiency and managing environmental impact:

Closed-Loop Fluid Management: The centrifuge spins drilling mud at high speed, separating fine cuttings (as small as 2-5 microns) from the fluid. The cleaned fluid is recycled back into the drilling process, drastically reducing the need for fresh water and additives.

Essential for Remote Operations: The diesel-powered hydraulic drive makes the system completely self-sufficient, ideal for exploration sites without reliable power.

Protects Equipment and Improves Results: By removing abrasive fine solids, the centrifuge reduces wear on pumps, drill strings, and the core barrel. Cleaner mud also helps maintain borehole stability and improves the quality of core samples。

For more cases info in detail, find Michael

Whatsapp: + 86 178 0179 9913

Email: michael@gnseparation.com