GN is a well-known brand from China, its full company name is HeiBei GN Solids Control Co.,Ltd which locadted in No.3 Industry Road, Dachang Chaobai River Development Area,Langfang, China; We are known around the world for unique innovation without compromise, sophistication while maintaining user simplicity, and superb service to our extremely wide customer base.specializing in supplying solids control& waste management equipment to the global market.

A mud recycling system in Horizontal Directional Drilling (HDD) is crucial for managing the drilling fluid (often referred to as mud) used during the drilling process. Here’s a breakdown of its components and functions:

Components of a Mud Recycling System:

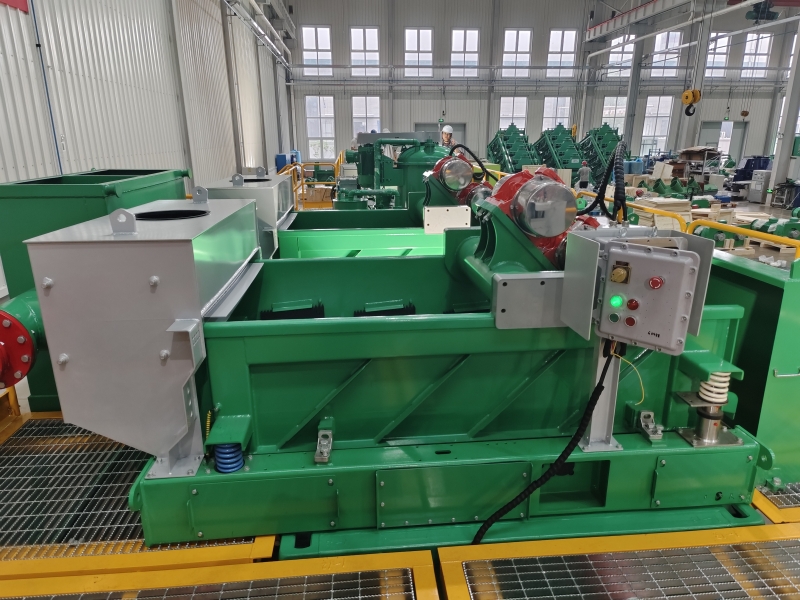

- Shale Shakers: These are the first line of defense in mud recycling. They separate the larger cuttings from the drilling fluid through vibrating screens.

- Desilters: After the shale shakers, the fluid typically goes through desanders and desilters. These units remove finer particles (sand and silt) to further clean the fluid.

- Storage Tanks: Cleaned mud is often stored in tanks for reuse, while waste material is disposed of or treated

- Pumps: These are essential for circulating the mud back to the drill bit and for moving it through the recycling system.

Functions:

- Cost Efficiency: Recycling drilling mud reduces the need for new mud, saving costs associated with material and disposal.

- Environmental Protection: Proper mud recycling minimizes waste and environmental impact, making HDD operations more sustainable.

- Operational Efficiency: Maintaining the right properties of the drilling fluid helps to optimize drilling performance, ensuring stability and efficiency.

Benefits:

- Reduced Disposal Costs: By recycling, companies can significantly lower the costs associated with mud disposal.

- Improved Drilling Performance: Clean, well-maintained mud can enhance drilling speed and reduce downtime.

- Sustainability: A recycling system supports greener practices in drilling operations.

In summary, a mud recycling system is essential for effective HDD operations, contributing to both operational efficiency and environmental stewardship.

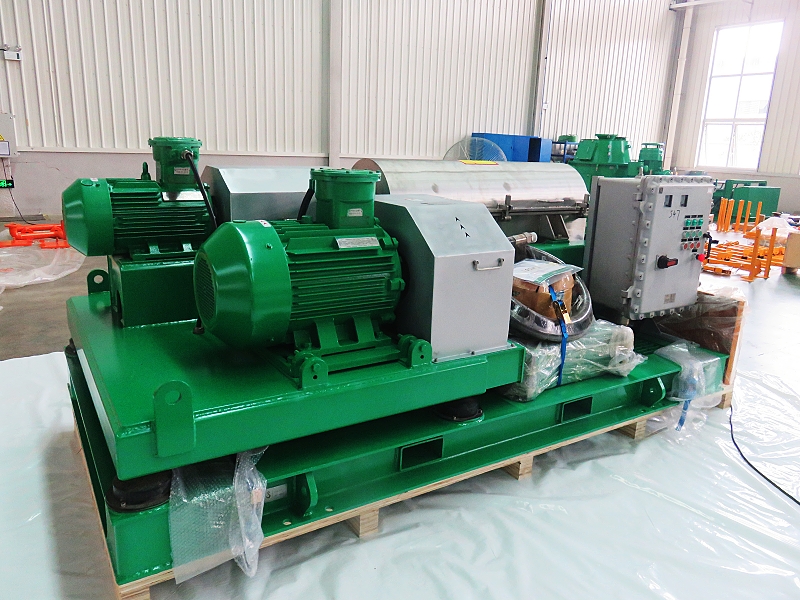

A mixing unit in HDD (Horizontal Directional Drilling) is essential for preparing the drilling fluid by combining water, additives, and bentonite (or other clay materials). Here are its key components and functions:

Components:

- Mixing Tanks: These hold the water and dry materials before mixing.

- Pumps: Transfer fluids and materials into the mixer.

- Mixing Blades: Agitate the components to ensure thorough blending.

- Control Systems: Monitor and adjust the mixing process for optimal fluid properties.

Functions:

- Homogenization: Ensures a consistent and uniform mixture, which is crucial for drilling performance.

- Additive Integration: Incorporates various additives to enhance the fluid’s properties, like viscosity and density.

- Real-Time Adjustment: Allows for modifications based on drilling conditions, ensuring the fluid remains effective.

Benefits:

- Enhanced Drilling Efficiency: Properly mixed fluids improve lubrication and cooling at the drill bit.

- Cost Management: Effective mixing minimizes waste and optimizes the use of materials.

- Adaptability: Can adjust to different soil and rock conditions for better performance.

In essence, a mixing unit plays a pivotal role in ensuring the drilling fluid is prepared to meet the specific needs of the HDD operation.

For our equipment brochure or more info, please find the contact info.

MichaelSong

Sales manager

Whatsapp:+86 17801799913

Email: michael@gnsolidscontrol.co