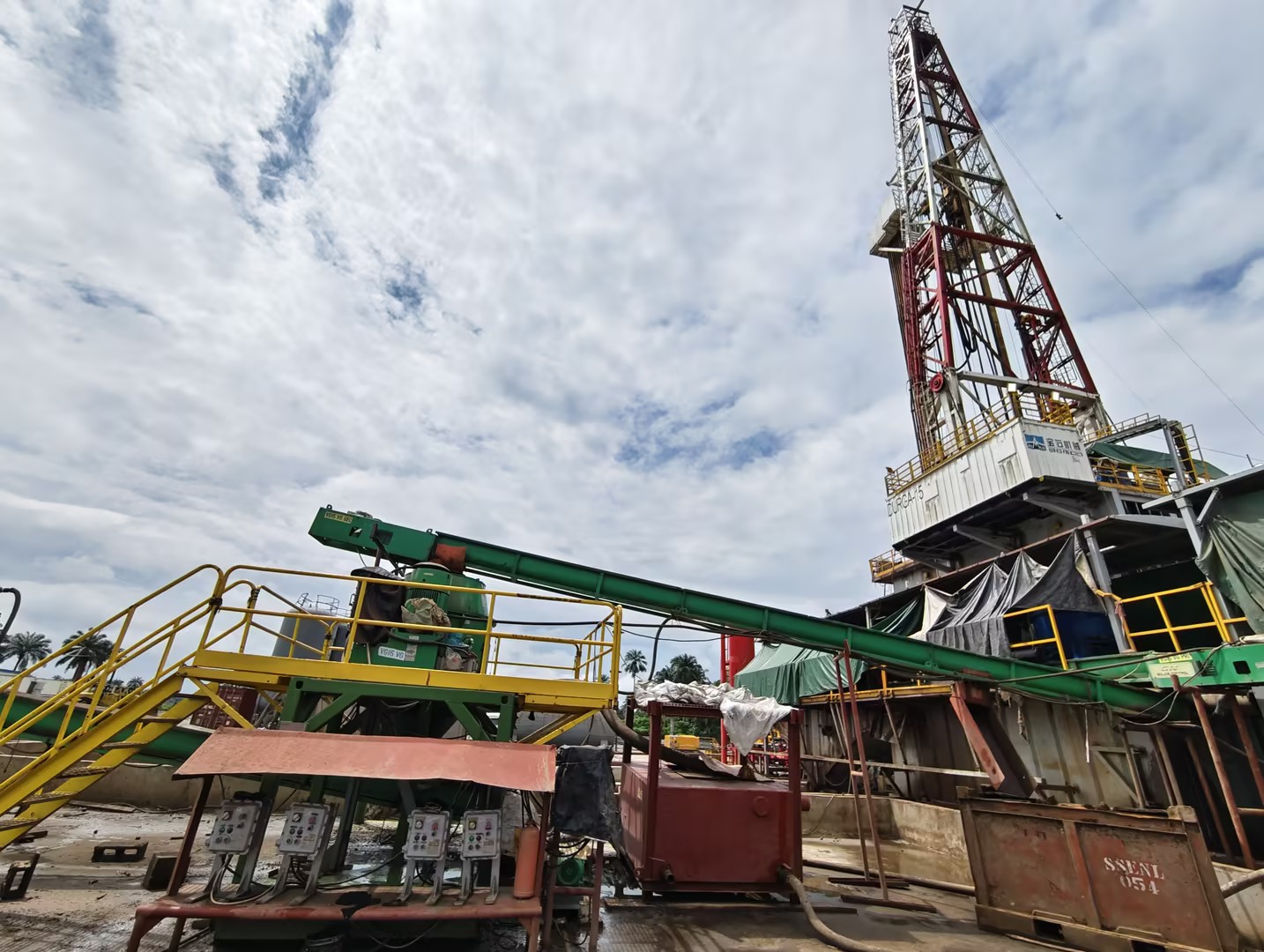

GN Solids Control Co., Ltd. is a major international manufacturer specializing in solids control and waste management equipment, primarily for the oil and gas, mining, and environmental sectors.

Product and Service Overview

GN provides a wide range of equipment and systems focused on separation technology. Their main product lines include-1-7:

Solids Control Equipment: The core of drilling fluid recycling, including shale shakers, desanders, desilters, decanter centrifuges, and mud tanks.

Waste Management Equipment: Systems to treat drilling waste and industrial sludge, such as vertical cuttings dryers and dewatering units, helping clients meet environmental regulations-6-7.

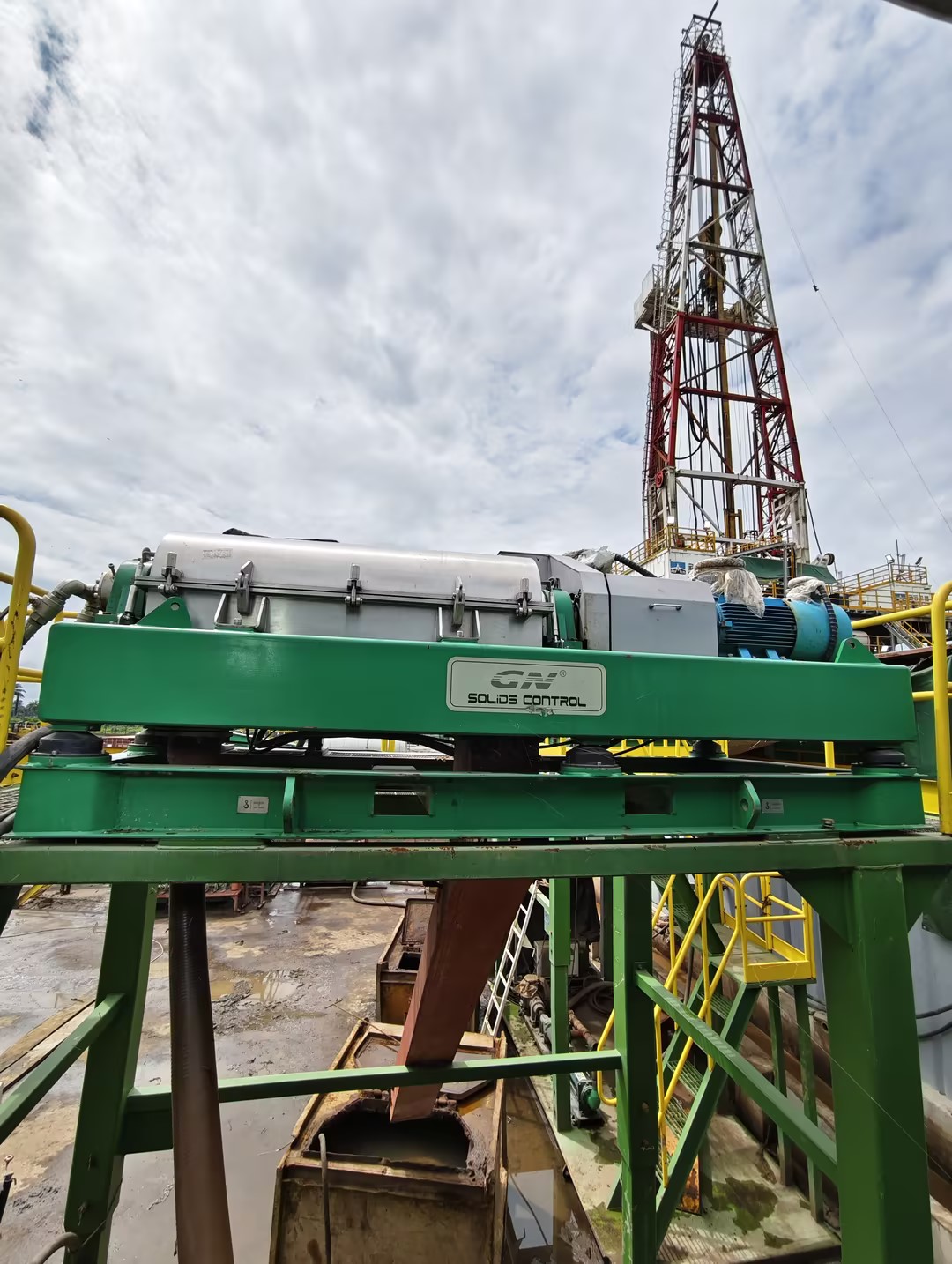

Industry Decanter Centrifuges: A flagship product line with models from 9 to 30 inches, used across various industries for liquid-solid separation-2.

Complete Systems: They also design and deliver integrated systems like drilling mud circulation systems, liquid mud plants, and slurry treatment plants for tunnel boring machines (TBM)-2-4.

🏭 Manufacturing and Operational Strengths

The company emphasizes strong in-house manufacturing capabilities and quality management:

Manufacturing Scale: It operates multiple factories in China with a total area exceeding 110,000 square meters, equipped with advanced machinery like automated welding robots and CNC centers-1-10.

Quality Assurance: GN holds several key international certifications. It is notably recognized as the first API-certified solids control equipment manufacturer from China and maintains ISO certifications for quality and environmental management-1-3.

Market Reach: Approximately 70% of its products are exported to over 70 countries worldwide, indicating significant international recognition-1-9.

🌍 Global Network and Recent Activities

GN supports its global customer base through a network of branch offices:

Americas: GN Solids America LLC in Houston, Texas, handles sales and service.

Asia-Pacific: GN Solids Australia operates from Brisbane.

Middle East & Africa: Operations are managed through GN Solids MENA in the UAE.

The company actively participates in major industry events. For example, it recently showcased its eco-friendly separation technology at the ADIPEC 2025 exhibition in Abu Dhabi.

Technical Specifications & Design

GN’s centrifuges are designed with durability and performance in mind:

Materials & Construction: Critical bowl sections are made from centrifugally cast duplex stainless steel (2304/2205) for strength and corrosion resistance. Key wear parts like the screw conveyor are protected with tungsten carbide tiles or ceramic plates-1-8.

Drive & Control: Models feature Variable Frequency Drive (VFD) for speed control and are often equipped with PLC systems for automation and monitoring. They offer models with explosion-proof (Exd) certification for hazardous environments-1-8.

Key Components: They use high-end bearings (SKF) and heavy-duty gearboxes. The pond depth (liquid level in the bowl) is often adjustable to optimize separation for different materials-1-8.

🌍 Industries Served

Beyond the oilfield, GN’s decanter centrifuges are used across multiple industries for solid-liquid separation-7-8:

Environmental: Municipal and industrial wastewater sludge dewatering.

Mining & Tunneling: Processing tailings, mineral washing water, and tunnel boring mud (TBM).

Chemical & Industrial: Processing various chemical slurries, pigments, and industrial wastes.

For more case info and relative drawing, please find Manager Michael.

Whatsapp: + 86 178 0179 9913

Email: michael@gnseparation.com