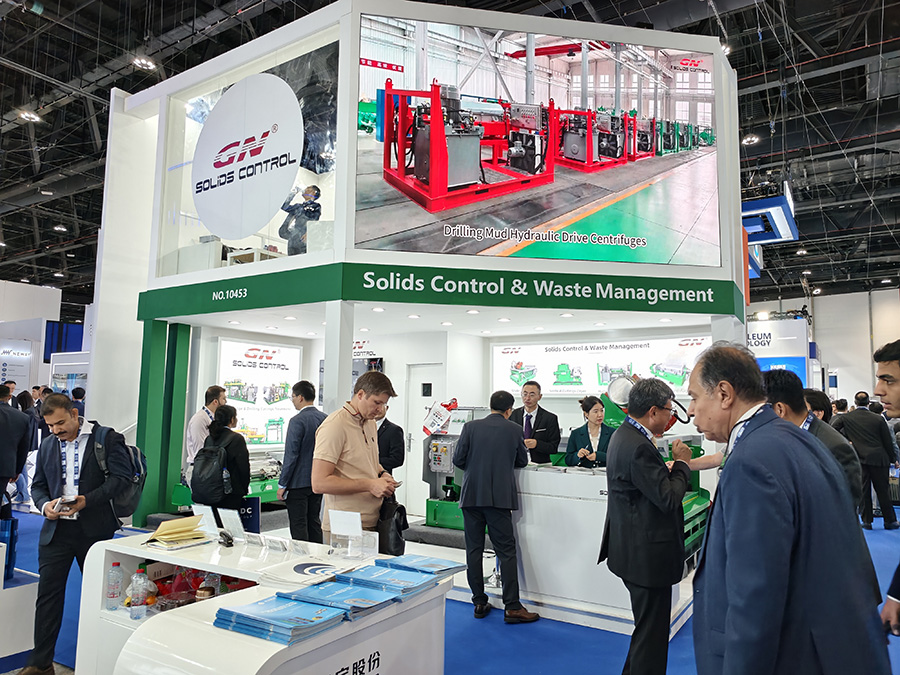

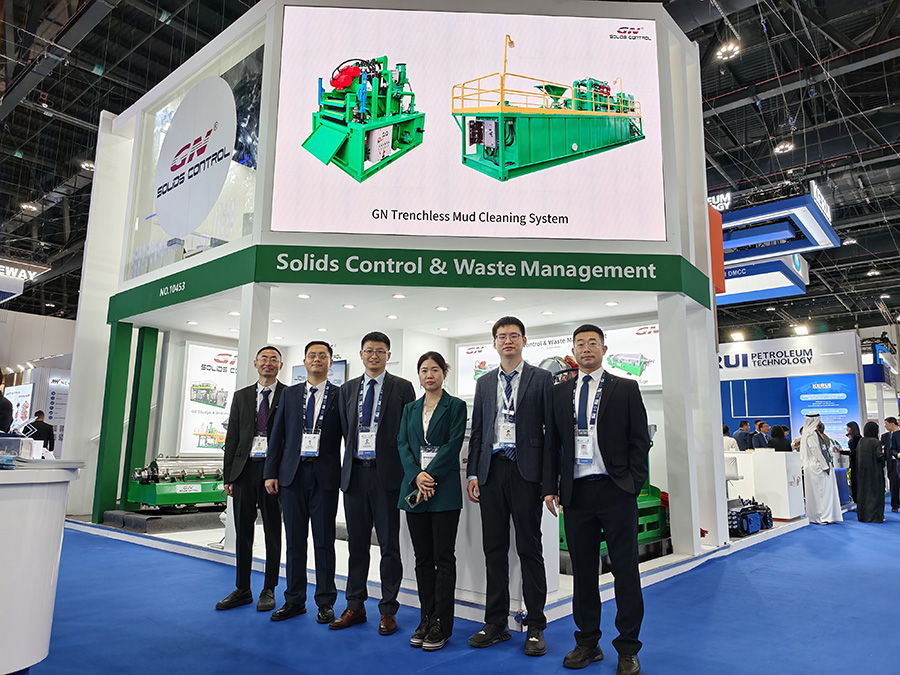

Company Overview

GN Solids Control Co., Ltd. is a Chinese manufacturer and global supplier specializing in solids control and separation equipment. They are a key player in providing complete system solutions for industries like oil and gas drilling, HDD (Horizontal Directional Drilling), mining, and environmental protection.

Core Products and Services

Their expertise lies in equipment that separates solids from liquids. Key product lines include:

Decanter Centrifuges: Their flagship product, available in various sizes and models (including 2-phase and 3-phase) for different applications.

Drilling Mud Systems: A full suite of equipment for processing drilling fluid, including:

Shale Shakers

Mud Cleaners

Desanders & Desilters

Degassers

Think of the centrifugal pump as the heart of the drilling fluid system. Its main job is to move large volumes of fluid continuously and reliably. In a typical drilling rig setup, its key applications are:

Feeding the Mud Pumps: The large, high-pressure triplex or duplex mud pumps are what push the fluid down the drill string. However, they are not good at pulling fluid. Centrifugal pumps (often called “charge pumps” in this role) are used to supply a steady, positive flow of fluid to the suction of the mud pumps, preventing cavitation and ensuring efficient operation.

Transferring Fluid Between Tanks: Moving drilling mud from one compartment of the mud tank to another, for example, from a settling tank to an active tank.

Powering Hydrocyclones: They provide the necessary pressure and flow to feed desanders and desilters (hydrocyclones), which remove fine drilled solids from the mud.

Supercharging: This is its most critical role. As mentioned above, it ensures the main mud pump has a constant, air-free supply of fluid at a positive pressure, which is essential for the mud pump’s performance and longevity.

Complete Solids Control Systems: They engineer and package the above equipment into integrated skidded or trailer-mounted systems for oil rigs, HDD projects, and TBMs (Tunnel Boring Machines).

Waste Management and Sludge Dewatering Systems: Equipment for environmental applications, such as treating industrial sludge and wastewater.

Global Presence

GN has a significant international footprint to serve its global clientele. They have established branch offices and subsidiaries in key regions, including:

GN Solids America LLC (United States)

GN Solids Mena (Middle East/North Africa, based in the UAE)

A branch office in Australia

For more cases info in detail, find Michael.

Whatsapp: + 86 178 0179 9913