GN Solids Control Co., Ltd. is a Chinese company specializing in the design, manufacturing, and service of solid control systems and related equipment for the oil and gas drilling industry.

Core Products & Services

- Solids Control Equipment

-

-

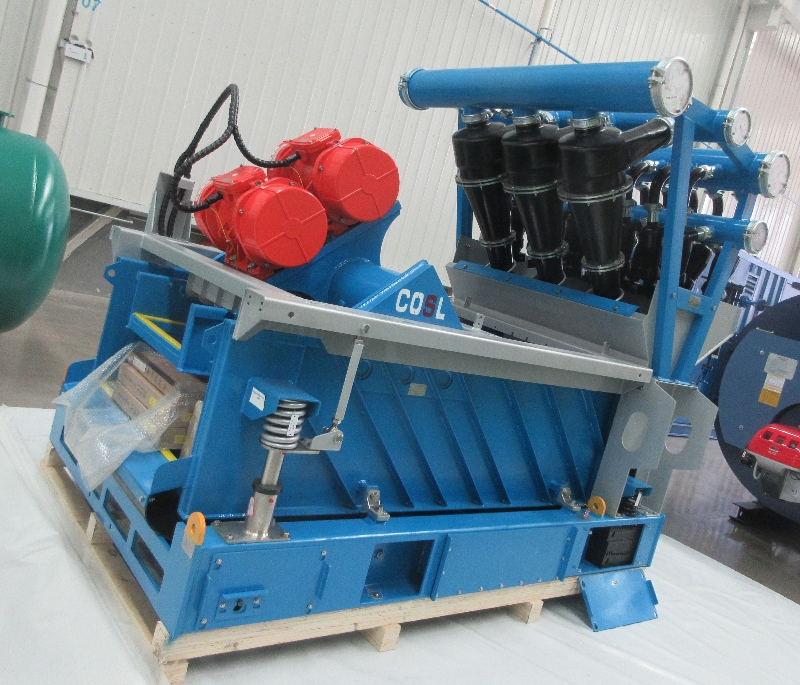

Shale shakers

-

Desanders & desilters

-

Decanter centrifuges

-

Mud cleaners

-

Vacuum degassers

-

2 .Drilling Waste Management

Cuttings dryers

Slurry separation systems

Thermal desorption units (for oil recovery from cuttings)

3. Mud Recycling Systems

Closed-loop systems for drilling fluid recovery

4. Customized Solutions

Containerized and skid-mounted systems for offshore/onshore drilling

A shale shaker is the first and most critical solids control equipment in drilling operations. It removes large drilled cuttings (≥75μm) from drilling fluid using vibrating screens, allowing clean mud to be reused.

Benefits of GN Shale Shakers

✔ Superior Solids Removal – Extends the life of downstream equipment (desanders, centrifuges).

✔ Low Maintenance – Easy screen replacement & durable construction.

✔ Energy Efficient – Optimized vibration motors reduce power consumption.

✔ Compatible with All Mud Types – Water-based, oil-based, synthetic-based.

✔ Global Certifications – API RP 13C, ISO 9001, CE, ATEX (for explosive environments).

A mud cleaner is a 2-stage or 3-stage solids control device that removes medium to fine particles (15-75μm) from drilling fluid after the shale shaker. It typically consists of:

Shale shaker (for coarse solids removal)

Hydrocyclones (desander + desilter for finer separation)

Bottom sieve (optional, for ultra-fine recovery)

GN Solids Control supplies high-efficiency mixing hoppers (also called mud hoppers or jet hoppers) for fast and uniform preparation of drilling fluids. These are essential for blending bentonite, polymers, additives, and weighting materials into water or oil-based mud systems.

For the prompt reply and cases, find MichaelSong.

Europe/Aisa Marketing Manager

Whatsapp: + 86 178 0179 9913