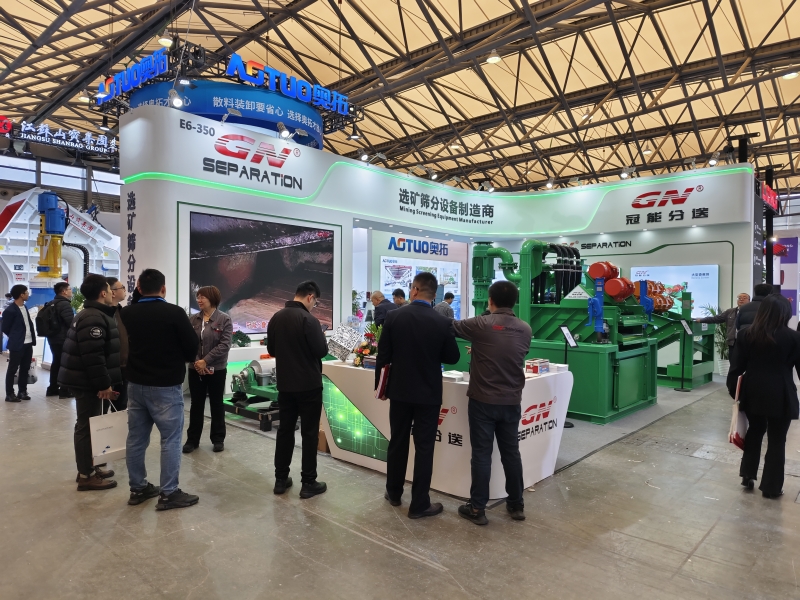

Bauma CHINA Shanghai Bauma Construction Machinery Exhibition, as the extension of the world-renowned German Bauma in China, has become a competition stage for global construction machinery companies. On this stage, many high-quality companies gathered, displayed tens of thousands of innovative products and technologies, and witnessed the inheritance of construction machinery wisdom.

GN is a well-known brand from China, its full company name is HeiBei GN Solids Control Co.,Ltd which locadted in No.3 Industry Road, Dachang Chaobai River Development Area,Langfang, China; We are known around the world for unique innovation without compromise, sophistication while maintaining user simplicity, and superb service to our extremely wide customer base.specializing in supplying solids control& waste management equipment to the global market.

Ore dressing, also known as mineral processing, involves separating valuable minerals from their ores using various techniques. One common equipment used in ore dressing is a vibrating shaker or vibrating screen, which is used to separate different sizes of particles in a slurry. These shakers use vibration to move particles of different sizes through a mesh or screen, allowing for the classification of materials.

Here’s how a vibrating shaker typically works in ore dressing:

- Vibration Mechanism: The shaker consists of a deck or a screen, which is mounted on springs or a frame that vibrates. This vibration can be produced by an electric motor or an eccentric mechanism.

- Screening: As the ore slurry is fed onto the vibrating screen, the vibration causes the particles to move across the surface. Larger particles tend to stay on the screen, while smaller particles pass through the mesh and are collected in a different area.

- Separation by Size: The vibrating shaker effectively separates the ore into different size fractions, which can then be processed separately. For example, fine particles may be sent to a flotation tank, while coarser materials might undergo further crushing or grinding.

- Materials: The vibrating shaker can handle a variety of materials, including ores, coal, sand, and gravel, depending on the type of screen mesh and the vibration characteristics.

- Applications: Commonly used in mining, coal processing, and aggregate sorting, vibrating shakers are crucial for improving the efficiency of ore dressing by ensuring the proper separation of particles before further processing.

A tailings dewatering centrifuge is a piece of equipment used in the mining industry to separate water from tailings, which are the waste materials left over after the extraction of valuable minerals from ore. The centrifuge uses centrifugal force to separate the solid particles in the tailings from the liquid, helping reduce the volume of tailings and recover water, which can be reused in the mining process.

Key Functions of a Tailings Dewatering Centrifuge:

- Separation of Solids and Liquids: The centrifuge spins at high speed, creating a strong centrifugal force that causes the denser solid particles in the tailings to move toward the outer wall of the rotating drum. The liquid phase, which is usually water, moves toward the center. The separation allows for the removal of excess water from the tailings.

- Water Recovery: One of the main benefits of using a dewatering centrifuge is the recovery of water, which can be returned to the mining process, reducing the need for fresh water. This is particularly important in regions where water resources are limited.

- Tailings Disposal: By dewatering the tailings, the amount of water in the waste material is reduced, allowing for safer, more efficient disposal. The dewatered tailings can often be transported and stored in a more manageable form, such as a thickened slurry or dry cake.

- Environmental Impact Reduction: Dewatering tailings helps reduce the environmental impact of tailings storage. By removing excess water, it prevents the potential for the tailings to leach harmful substances into the environment, and it also reduces the risk of tailings dam failure.

How a Tailings Dewatering Centrifuge Works:

- Feeding: The tailings slurry (a mixture of fine ore particles and water) is pumped into the centrifuge drum.

- Rotation: The drum of the centrifuge spins at high speeds, typically between 1,000 to 4,000 rpm, generating centrifugal force.

- Separation: As the drum spins, the solid particles, which are heavier, move toward the outer wall of the drum, while the water (or liquid phase) remains closer to the center. A series of discharge ports are used to remove the water from the center of the drum.

- Discharge of Solids: The dewatered solids are discharged from the outer part of the drum, often in the form of a wet cake or slurry with reduced water content.

Types of Tailings Dewatering Centrifuges:

- Decanter Centrifuge: This is the most common type used for tailings dewatering. It consists of a horizontal drum and a screw conveyor that helps transport the solids to the discharge area. Decanter centrifuges are highly effective at producing a dewatered tailings cake with a low water content.

- Peeler Centrifuge: This type of centrifuge is generally used when extremely high solid-liquid separation efficiency is required. It typically involves a vertical drum and a series of scraping mechanisms to remove the dewatered solids.

Benefits:

- Efficient Water Recovery: Tailings dewatering centrifuges recover significant amounts of water, which can be reused in the mining operation.

- Compact Design: These centrifuges are often compact and can be integrated into existing processing plants without taking up excessive space.

- Reduced Tailings Volume: By reducing the water content of the tailings, the volume of material to be disposed of is significantly decreased, reducing storage space and improving tailings management.

Applications:

- Mining Operations: For dewatering tailings from various mineral processing methods (such as flotation, gravity separation, or leaching).

- Coal Industry: Dewatering fine coal tailings to recover water and reduce waste volume.

- Environmental Protection: Reducing the risk of contamination and improving the environmental footprint of mining operations.

A sludge vacuum pump is a type of vacuum pump specifically designed to handle and transport sludge, which is a semi-solid material often found in wastewater treatment, mining operations, or industrial processes. Sludge is typically a mix of water and solid particles, and its handling requires specialized pumps that can move this thick, viscous mixture efficiently. Sludge vacuum pumps are particularly useful in applications where the transfer of slurry, slurry-like materials, or thick sludge is needed.

How a Sludge Vacuum Pump Works:

A sludge vacuum pump works by using suction to draw sludge from a tank, pit, or other collection area, and then moving it through a pipe or hose to a storage or disposal site. The main mechanism of these pumps relies on the vacuum (negative pressure) created to suck up the sludge. The specific pump design depends on the type of sludge being handled and the required flow rate.

Key Components:

- Vacuum Tank: This is where the sludge is initially collected. It typically has a vacuum port through which the sludge is sucked into the pump system.

- Vacuum Pump: The pump is the heart of the system, creating the suction force that moves the sludge.

- Discharge Hose or Pipeline: Once the sludge is collected and pumped, it is moved through a hose or pipeline to the desired location, whether it’s a sludge treatment facility or a disposal site.

- Control System: Modern sludge vacuum pumps are often equipped with control systems that monitor the vacuum pressure, flow rate, and pump performance.

A mud recycling system is an engineered solution used to treat and manage drilling mud, also known as drilling fluid, in various industries, particularly in oil and gas drilling, mining, construction, and geotechnical engineering. Drilling mud is used to cool and lubricate the drill bit, remove drill cuttings from the wellbore, and maintain pressure during drilling operations. Over time, this fluid becomes contaminated with cuttings, solids, and other impurities, necessitating treatment and recycling to ensure continued efficiency, reduce environmental impact, and cut costs.

Key Components of a Mud Recycling System:

A typical mud recycling system involves a combination of equipment designed to clean, treat, and recycle the drilling fluid. The main components include:

- Shale Shakers:

- These are vibrating screens used to separate large solids (like drill cuttings) from the drilling mud. The shaker uses vibration and screens of different mesh sizes to filter out unwanted solids. The screened mud is sent to other components for further treatment.

- Desander:

- A desander is a cyclone separator that removes finer solids (typically in the 40-100 microns size range) from the mud. It uses centrifugal force to separate heavier solids from the fluid. Desanders are often used in combination with shale shakers and desilters for more effective solids control.

- Desilter:

- Similar to a desander, a desilter is another cyclone-based system but is designed to remove even finer solids (usually 15-40 microns). It is typically the final step in removing solids from the drilling mud before the fluid is returned to the wellbore.

- Centrifuges:

- Decanter Centrifuges are used to further separate fine solids from the drilling mud. By spinning the mud at high speed, the centrifuge uses centrifugal force to separate solids from the fluid. Centrifuges are highly effective at cleaning mud and can recover valuable base fluids for reuse.

- Mud Agitators:

- These devices are used to keep the drilling mud in suspension and prevent solids from settling. Agitators help to maintain the homogeneity of the mud, ensuring efficient mud circulation during drilling.

- Vacuum Degasser:

- This equipment removes dissolved gases (such as methane or hydrogen sulfide) from the mud. Vacuum degassers are particularly useful when dealing with gas-cut muds, which can affect the mud’s properties and lead to operational issues.

- Mud Cleaners:

- A mud cleaner combines the functions of a shale shaker, desander, and desilter into one unit. It typically consists of multiple stages of cyclonic separators and vibrating screens to effectively clean the drilling fluid.

- Flocculant or Polymer Dosing System:

- Flocculants or polymers are often added to help clump together small, dispersed particles in the mud, which can then be removed by the filtration or centrifugation process.

- Mud Tanks:

- Mud tanks are large containers used for holding the drilling fluid. They store the drilling mud before it is pumped down the wellbore and after it has been recycled. Mud tanks typically include features like mixing systems, pumps, and pipelines to move the fluid.

Steps in a Mud Recycling Process:

- Solids Removal:

- The first step is to separate the larger solids (such as drill cuttings) using shale shakers or desanders. These devices help reduce the amount of solid material in the mud.

- Fine Solids Separation:

- After the initial separation, finer solids are removed through desilters and centrifuges. These systems help to remove smaller particles that are suspended in the mud, improving the mud’s flow properties and reducing the need for frequent fluid replacement.

- Gas Removal:

- If the mud is contaminated with gases, a vacuum degasser is used to remove any entrained gases (like methane or hydrogen sulfide), ensuring the stability and safety of the mud.

- Mud Treatment:

- After solids and gases are removed, polymers or flocculants may be added to help further clean and stabilize the mud. This step improves the fluid’s viscosity, suspension properties, and lubrication capabilities.

- Recycling:

- Once the drilling mud is cleaned and treated, it is pumped back into the system for reuse. This cycle can continue throughout the drilling process, reducing waste and operational costs.

Benefits of a Mud Recycling System:

- Cost Reduction:

- Recycling drilling mud significantly reduces the need to purchase fresh mud, leading to substantial cost savings. The reusable base fluid can be treated and used multiple times, especially in large-scale drilling operations.

- Environmental Benefits:

- Proper treatment and recycling of drilling mud reduces the environmental impact by minimizing the volume of waste materials that need to be disposed of. Many systems are designed to reduce the amount of solid waste and ensure that chemicals are not released into the environment.

- Improved Drilling Efficiency:

- Clean, well-maintained drilling mud helps maintain optimal drilling parameters. Mud recycling systems ensure that the mud’s properties remain consistent, providing better lubrication, cooling, and cuttings removal.

- Waste Minimization:

- Recycling systems allow for a reduction in the volume of waste mud and solids, which can be difficult and expensive to manage. This contributes to cleaner drilling operations and improved waste disposal strategies.

- Better Mud Quality:

- Continuous recycling and treatment help maintain the quality and performance of the mud. It ensures that the fluid has the right viscosity, density, and solids content to meet drilling requirements.

- Oil and Gas Drilling:

- In the oil and gas industry, mud recycling systems are used during both offshore and onshore drilling operations to manage the large volumes of drilling fluid required and to minimize waste.

- Mining:

- In the mining sector, especially in operations like diamond drilling and core drilling, mud recycling helps manage the fluids used in exploration drilling.

- Construction and Geotechnical Drilling:

- In construction, particularly when drilling for foundations or underground structures, recycling drilling fluids can reduce waste and improve safety.

- Environmental Remediation:

- In certain cases, mud recycling systems are used in environmental projects to clean up contaminated soil and water, particularly in areas where traditional waste disposal is impractical or costly.

For the prompt reply, please find the contact info.

MichaelSong

Sales manager

Whatsapp:+8617801799913

E: michael@gnsolidscontrol.co