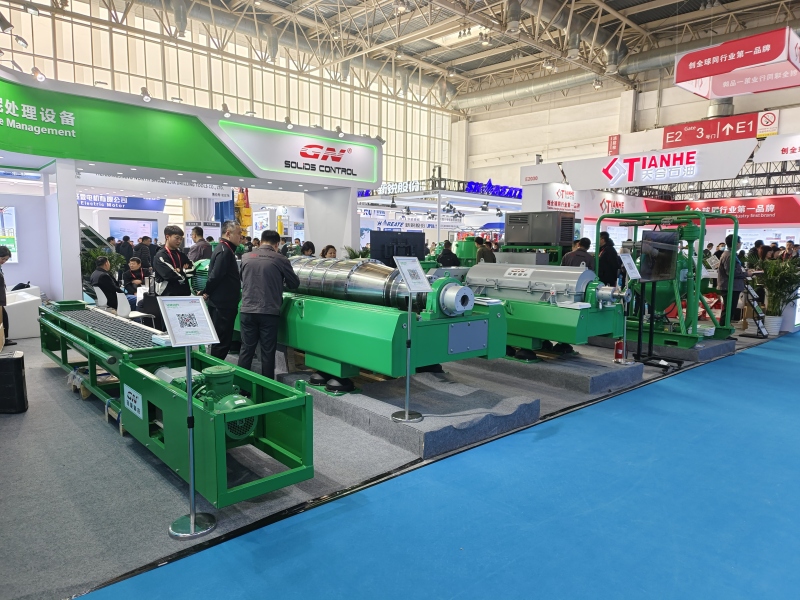

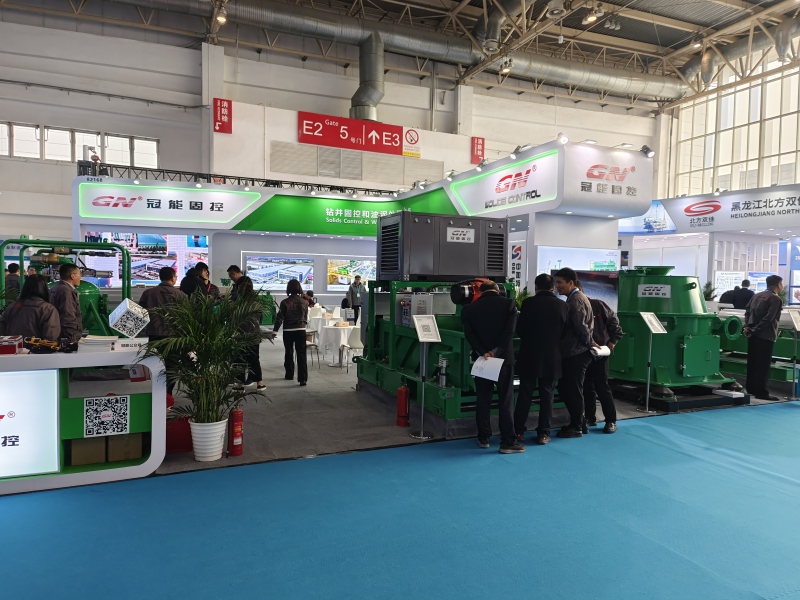

The CIPPE Exhibition, also known as the China International Petroleum & Petrochemical Technology and Equipment Exhibition, is one of the largest annual petroleum exhibitions in the world. It typically takes place in Beijing, China. The event showcases the latest technological advancements, equipment, and services in the petroleum and petrochemical industries, attracting exhibitors and attendees from around the globe. CIPPE serves as a platform for industry professionals to network, exchange ideas, and explore business opportunities in the oil and gas sector. Exhibitors often include companies involved in exploration, drilling, refining, transportation, and distribution of petroleum and petrochemical products.

Decanter Centrifuge.

A centrifuge is a device that employs a high rotational speed to separate components of different densities. This becomes relevant in the majority of industrial jobs where solids, liquids and gases are merged into a single mixture and the separation of these different phases is necessary. A decanter centrifuge (also known as solid bowl centrifuge) separates continuously solid materials from liquids in the slurry, and therefore plays an important role in the wastewater treatment, chemical, oil, and food processing industries. There are several factors that affect the performance of a decanter centrifuge, and some design heuristics are to be followed which are dependent upon given applications.

The operating principle of a decanter centrifuge is based on separation via buoyancy. Naturally, a component with a higher density would fall to the bottom of a mixture, while the less dense component would be suspended above it. A decanter centrifuge increases the rate of settling through the use of continuous rotation, producing a G-force equivalent to between 1000 and 4000 G’s. This reduces the settling time of the components by a large magnitude, whereby mixtures previously having to take hours to settle can be settled in a matter of seconds using a decanter centrifuge. This form of separation enables more rapid and controllable results.

With a 3 phase decanter centrifuge, it is possible to separate 3 phases from each other in one process step only. For example, two liquids which cannot be mixed because of different densities (e.g. oil and water) are separated from a solids phase. The heavy liquid (water) collects in the middle between the oil and the solids layer. Thus the two liquids separated from each other can be drawn off from the decanter. The solids are transported via the scroll to the discharge openings as it happens also in 2-phase separation.

Typical applications of 3-phase separation are the production of edible oils such as olive oil, oil sludge processing, the production of biodiesel etc.

For our equipment brochure or more info, please visit our unique official website: www.gnsolidscontrol.com

MichaelSong

market manager

Whatsapp:+86 17801799913