MUD-WATER-SEPARATION-SYSTEM-AND-MUD-RECOVERY-SYSTEM-ARE-SOLD-TO-TRENCHLESS- CUSTOMERS-IN-ASIA

GN is a well-known brand from China, its full company name is HeiBei GN Solids Control Co.,Ltd which locadted in No.3 Industry Road, Dachang Chaobai River Development Area,Langfang, China; We are known around the world for unique innovation without compromise, sophistication while maintaining user simplicity, and superb service to our extremely wide customer base.specializing in supplying solids control& waste management equipment to the global market.

This Mud Cleaning System, also known as a solids control system, is an integral part of the drilling process in the oil and gas industry. Its primary purpose is to remove solids and other impurities from the drilling mud or fluid used during drilling operations. Clean drilling mud is essential for maintaining drilling efficiency, protecting drilling equipment, and ensuring the wellbore stability. Here are some key components and functions of a typical mud cleaning system:

- Shale Shaker:

- Function: The shale shaker is the first stage of the mud cleaning system. It uses vibrating screens to separate large solids (drill cuttings) from the drilling mud.

- Operation: Vibrations from the shaker convey the mud and cuttings over the screens, allowing the mud to pass through while retaining the larger particles.

- Desander:

- Function: Desanders are hydrocyclone devices designed to remove sand-sized particles (typically between 40 and 100 microns) from the drilling mud.

- Operation: Mud is pumped into the desander, and centrifugal force separates the solids, which are then discharged, leaving cleaner mud.

3.Mud Tank:

- Function: Mud tanks are used to store and circulate the drilling mud through the cleaning system.

- Operation: Mud is agitated and mixed in the tank before being processed through the various cleaning stages.

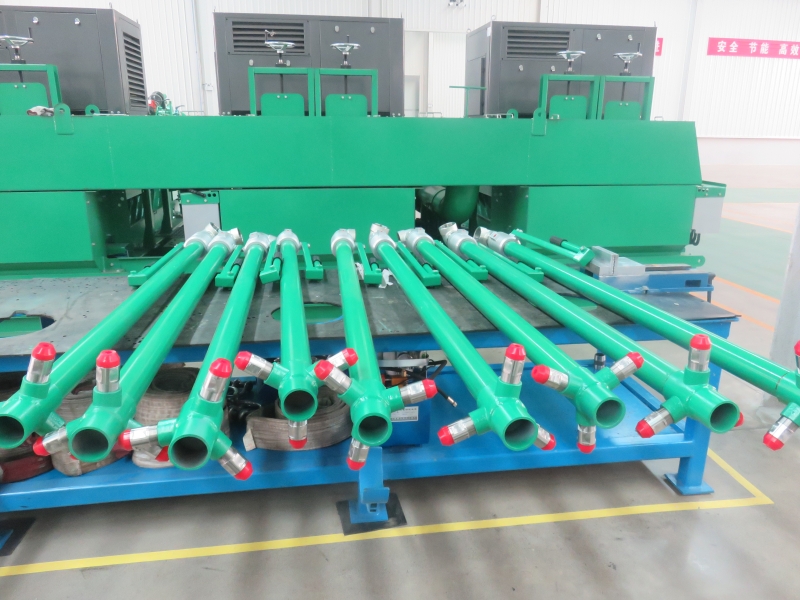

4.Pumps:

- Function: Pumps are used to transport the mud between different components of the cleaning system.

- Operation: Pumps circulate mud from the tank to the shale shaker, desander, desilter, and centrifuge, facilitating the continuous cleaning process.

The mud cleaning system ensures that the drilling fluid remains within specified parameters, controlling viscosity, density, and other properties. This is crucial for efficient drilling, wellbore stability, and environmental compliance.

Please note that specific configurations and components of mud cleaning systems may vary based on the drilling operation and equipment used.

For our equipment brochure or more info, please visit our unique official website: www.gnsolidscontrol.com

MichaelSong

Sales manager

Whatsapp: +8617801799913