GN Solids Control is a manufacturer of solids control and waste disposal equipment. After more than 10 years of continuous development, GN Solid Control has established overseas branches in the United States and Russia.

The new crown pneumonia has brought about a severe economic recession since World War II. Fortunately, with the successful launch of the vaccine, our lives have gradually moved on to the right track. Compared with the oil industry, as oil prices continue to rise, the situation in the oil industry is getting better and better.

In March and November 2021, GN Solids Control once again delivered a drilling mud mixing tank and centrifugal pump to an engineering company. The detailed introduction of the product is as follows:

1. GN Solids Control drilling mud mixing tank

The drilling mud mixing tank includes 2 small circular tanks. A crown energy jet slurry mixing centrifugal pump with a mud bucket is used to transport the chemicals to the first tank. Two centrifugal pumps connected in parallel are connected to the tank through manual butterfly valves. Through the opening and closing of the butterfly valve, any GN centrifugal pump can be used to transport chemicals. After the first mud tank is fully stirred, the equipped mud is transported to the second tank through the connecting pipeline, and the mud can be directly used for the drilling rig. In order to ensure uniform mixing of drilling mud, each mud tank is equipped with a mud agitator.

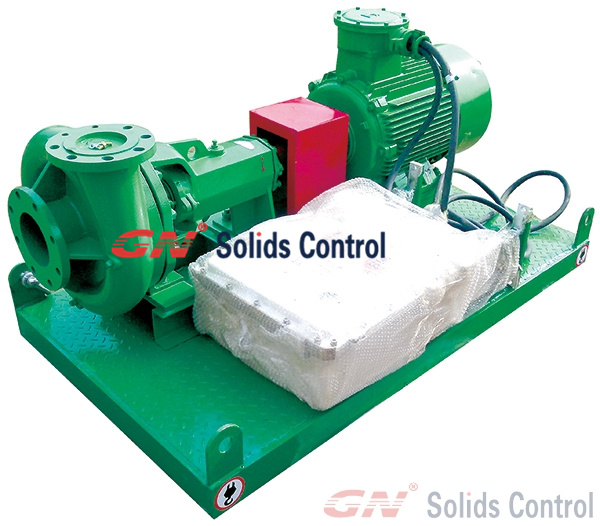

2.GN Solids Control jet mixing centrifugal pump

The GN Solids Control jet centrifugal pump is a centrifugal pump with a venturi hopper. Drilling chemicals are added to the mixing tank through a mud funnel, and then pumped into the mixing tank.

Welcome everyone to contact the professional team of GN Solids Control, we will provide you with cost-effective solutions.