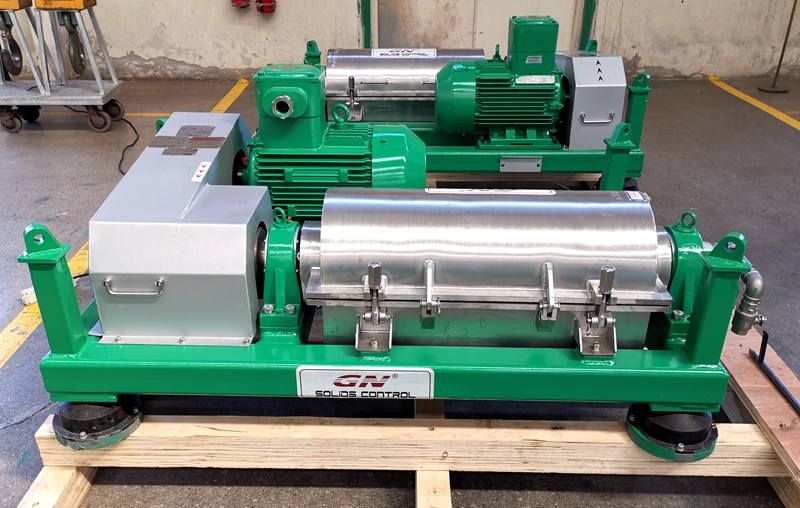

Recently, GN Solids Control have finish 1 set waste treatment centrifuge

Centrifuge for separating finer solid particles and oil water, using a patented technologies and top-level materials and processes, imported bearings and components of internationally renowned brands to improve the stability of the equipment and prolong its service life.

For the GN solid control decanter centrifuges, the main drive motor is converted to stock through a differential drive centrifuge. back motors directly drive the auger and differential with its operating speed is fixed.

GN Solids Control is the first manufacturer of mud solid-control equipment in the country to pass the certification export standard qualification.,the centrifuge can work with other equipment together like shale shaker

Centrifuge use for different job like oil sludge treatment

1. Barite recovery centrifuge: The rotation speed is about 1800 RPM, the “G” value is about 700, the low-density separation point: 6-10 μm; the high-density separation point: 4-10 μm.

2. Large-capacity centrifuge: rotating speed is about 1900 ~ 2200RPM, “G” value is about 800, low-density separation point: 5 ~ 7μm (without weighting drilling fluid), used to exclude low-density solid phase;

3. High-speed centrifuge: The rotation speed is about 2500 ~ 3300RPM, the “G” value is about 1200 ~ 2100, and the low-density separation point: 2 ~ 5μm is mainly used to remove the low-density content of unweighted drilling fluid.

The suspension to be separated and the accelerating sedimentation agent are continuously transported into the centrifuge through the feed pipe, after being accelerated by the acceleration cone of the screw pusher, they enter the high-speed rotating centrifuge drum, and the suspension is An annular liquid flow is formed in the drum, and the solid particles rapidly settle to the inner wall of the drum under the action of centrifugal force. The differential speed of the centrifuge drum and the spiral produced by the differential drives the sediment to the drum cone by the spiral At the end of the dry discharge area, through the two-way squeezing of the screw thrust and the centrifugal component force, so that the sediment is further extruded and dehydrated, it is discharged from the slag discharge port of the small end of the drum. The depth of the liquid layer of the annular liquid flow can be adjusted by the overflow baffle at the big end of the drum to obtain different separation effects of sediment and clear liquid. The separated clear liquid is discharged through the overflow port of the centrifuge, the sediment and the separated liquid are collected into the respective collection bins in the casing, and finally discharged out of the machine under the action of gravity.

More question,welcome contact GN Solids Control