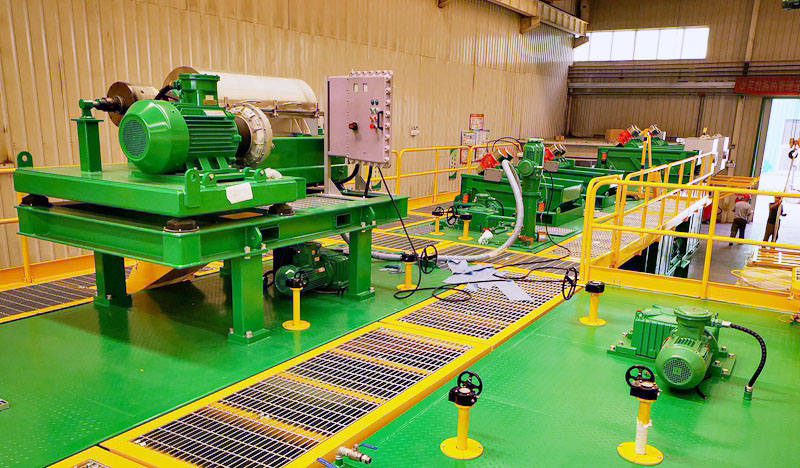

This week, at the GN Solids Control workshop, a drilling rig mud recycling system is in the factory trial assembly, and the system will be shipped to a drilling company from Hebei.China, GN Solids Control has more than 10 years of experience in customizing mud circulation systems.

This mud recycling system contains four levels of solid control equipment. The main supporting equipment is as follows:

1: Two drilling fluid shale shakers GNZS703F are used for the first-level solid control treatment. A mud distribution pipe is provided between the two shaker screens, which can evenly distribute drilling mud to the two shaker screens. GN Solids Control drilling fluid shaker screen has a simple structure and uses patented net sealing technology to ensure stable performance.

Two: GNZJ752-2S desilter and GNZJ752F-12N desilter are designed as small cleaners, and the area of underflow screen is 1.4m2, which is about the same as that of conventional desilter and desilter underflow screens, and it also reduces the area reasonably . With this small shaker, the sludge discharged from the cyclone will be dried again to recover more drilling fluid and reduce waste emissions. All GN Solids Control shaker screens use composite screens for long life and good rust resistance.

Three: GNLW452 decanter centrifuge, can be used for heavy stone recovery or fine particle separation. All GN Solids Control decanter centrifuges use hard alloy plates to protect the screw blades and solid exhaust wear-resistant sleeves, which can ensure stable operation at low cost for a long time.

All mud recycling solid control equipment is installed on 3 mud tanks, including mud circulation and mud mixing. This mud system is equipped with a total of 3 sand pumps, 2 of which are used to feed the slurry to the cyclone, and the other is connected to the mud bucket for mud mixing.

Prior to shipment, all mud recycling systems at the GN Solids Control plant will be tested for installation, equipment will be tested for water, and leak tests will be performed on storage tanks to ensure stable work on site.

For more information on GN Solids Control, please feel free to contact us.