To acheive zero discharge for the drilling mud, GN Solids Control provide the dewatering decanter centrifuge with the flocculent unit.

The GN1500 Series 20FT Dewatering Unit provides a process of chemically enhanced configuration to remove the fine solids less than 5 microns from the water based drilling fluids.

Traditional Solids Control Equipment:

As it known that traditional solids control equipments like shale shaker,desander desilter, and decanter centrifuge will removes solids upper than 5 microns, for colloidal-size particles which is less than 5 microns will build up in the drilling mud system. To maintain the drilling mud properties, the operators have to dilute the drilling fluids with water, this consumes more water and create more drilling waste.

Advantage to use flocculent unit for the dewatering decanter centrifuge:

By utilizing the GN1500 20FT dewatering flocculent unit, the result is a chemically enhanced flocculation of colloidal and ultra-fine drilled solids that can be efficiently removed with a GN dewatering centrifuge.

For limited and zero discharged closed loop system, the GN dewatering unit is a very important unit to keep the mud clean and reduce the drilling waste which has to be sent for treatment and disposal. Before entering the dewatering phase, for the weighted drilling mud, firstly it enters a barite recovery centrifuge to recovery the barite to the active mud system.

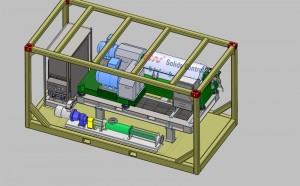

The GN 20 Ft containerized dewatering unit can be transported as a standard 20 ft container The system includes all the standard dewatering components .GN also have the dewatering decanter centrifuge available can be mounted on a separate telescoping skid or on the drilling mud tank. Continue reading “Dewatering Centrifuge with FLOCCULENT UNIT”