Drill solids are the main contaminant of all drilling fluids and therefore their control is of the utmost importance. There are 3 main ways of controlling solids:

• Dilution

• Mechanical removal

• Gravity Settling

I ever saw in the water well drilling site in Mongolia that they do not use any solids control equipments but only dig several mud pits, by this way, it is very low efficiency and Environmental Pollution.

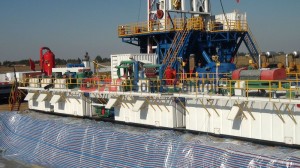

Solids control system is a way for mechanical removal the drill solids. Mainly it includes screen devices & Centrifugal Separation Devices. Screen devices is the most important equipment called shale shaker. In the future of solids control system, shale shaker will become the only solids control equipment which will be used instead of desander, desilter, mud cleaner, decanter centrifuge by improvement of its design. At present, linear motion shale shaker is the most popular vibration mode shale shaker.

But the arrangement of vibration motor various by different shale shaker manufacturer. Sometimes it is vertical installed, sometimes it is horizontal installed, it doesnot mean that horizontal installed shale shaker must be balanced elliptical motion shale shaker, it might be linear motion shaker.