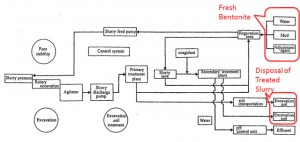

In the other days, a customer asked us about slime dewatering system. Their main purpose is to take out of the drain pits, means do not need very clean water. Then they tell us the distribution of the solids contents.

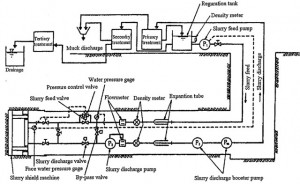

After know more about our equipments such as GNZS83-2 shale shaker, GNZJ83-2 mud cleaner, SB4x3x11 centrifugal pump and so on. They have got some questions, and I want to share then if you have the same questions, take this for your reference.

By the way, after export to more than 30 countries over the world, and we are more professional at solids liquids separation now. Here is the questions:

1) is it possible to produce the dewatering system with productivity less then 50m3/h?

Yes. Actually if you want drier solids, a little less is better.

2) how you’d suggest to unload filtered material to the carts from the system?

the filtered material can be loaded to the cars directly, pls kindly find the picture in the introduction document.

3) how do you load the system with watered slime? Continue reading “Q&A of Slime Dewatering System”