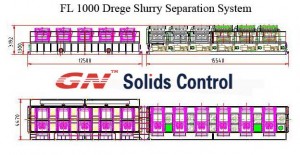

After dredging work, we should separate the slurry, for envioment friendly or other purpose. GN FL 1000 is one perfect system for about 3000 gpm capacity. We will take this for example to introduce How the slurry separation work.

How the Slurry Separation Work

1. Entry: the dredged slurry enters the shale shaker directly from the dredge. In GN FL 1000, the slurry enters into the GNZS 83-3 shale shaker, (5 pcs)

2. Shale Shaker: there are 5 GNZS 83-3 shale shakers in FL 1000, treating capacity is 3000 gpm. With the proper shaker screen, the debris like grass, roots, leaves, cans, plastic, rags, and bottles can be separated, then the slurry to the next stage is in conditon that the biggest particles is 47-76um.

3. Desanding tank: The slurry going through the shale shaker, and drop into a tank, where it is picked up by a centrifugal pump.

4. De-sanding and De-silting: the pump, means SB 8*6*14 centrifugal pump moves the slurry to the second phase. Then it passs the desanding hydro-cyclones, to the desilting tank. Then the slurry will be pumped again to the desilting hydrocyclones. Dropped into another process tank. Until now the debris bigger than 20um (15-47um) are separated. Equipments referred is ZQJ 250 desander, and ZQJ 100 desilter. Continue reading “Operation of Dredge Slurry Separation System”