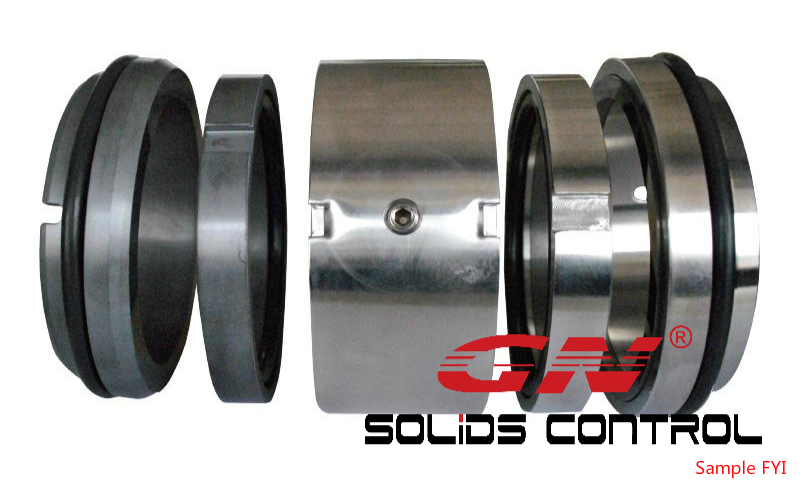

Mechanical sealing for centrifugal pump

Centrifugal pump is the regular pump use for solids control system and drilling oil system,GN solids control try supply reliable pump to every client

Mechanical seal as important point to decide pump’s quality and service life,was pay attentioned by GN solids control

The mechanical seal is simply a method of containing fluid within a vessel (typically pumps, mixers, etc.) where a rotating shaft passes through a stationary housing or occasionally, where the housing rotates around the shaft.

When sealing a centrifugal pump, the challenge is to allow a rotating shaft to enter the ‘wet’ area of the pump, without allowing large volumes of pressurized fluid to escape.

To address this challenge there needs to be a seal between the shaft and the pump housing that can contain the pressure of the process being pumped and withstand the friction caused by the shaft rotating.

Here we compare two different way

Traditional method

Gland packing is still commonly used in many applications, however increasingly users are adopting mechanical seals for the following reasons:;

- The friction of the shaft rotating wears away at the packing over time, which leads to increased leakage until the packing is adjusted or re-packed.

- The friction of the shaft also means that packing also needs to be flushed with large volumes of water in order to keep it cool.

- Packing needs to press against the shaft in order to reduce leakage – this means that the pump needs more drive power to turn the shaft, wasting energy.

- Because packing needs to contact the shaft it will eventually wear a groove into it, which can be costly to repair or replace.

Why choose mechanical sealing

- No “visible” leak – seals do leak vapour as the fluid film on the faces reaches the atmospheric side of the seal faces.

- This would approximate to 1/2 teaspoon a day at normal operating pressures and temperatures, if it were captured and condensed.

- Modern cartridge seal designs do not damage the pump shaft or sleeve.

- Day to day maintenance is reduced as seals have inboard springs which make them self-adjusting as the faces wear.

- Seals have lightly loaded faces which consume less power than gland packing.

- Bearing contamination is reduced in normal operation as the lubricant does not become affected by seal leakage and wash out.

- Plant equipment also suffers less from corrosion if the product is contained in the pump.

- Vacuum can also be sealed with this technology, a problem for packing as air was drawn into the pump.

- Less wasted product will save money, even water is an expensive commodity and less clean up of the area will be needed.

To give client’s suitable product,GN solids control will always develop the design and improve service